Die Branche der Elektrofahrräder (E-Bikes) hat in den letzten Jahren ein explosionsartiges Wachstum erlebt, das durch die Überlastung der Städte, Umweltbedenken und die Nachfrage der Verbraucher nach effizienteren Lösungen für die persönliche Mobilität angeheizt wurde. Im Zuge der Weiterentwicklung der E-Bike-Technologie haben sich Motoren mit Mittelantrieb als Schlüsselinnovation herauskristallisiert, die gegenüber herkömmlichen Nabenmotoren erhebliche Vorteile bieten. Im Gegensatz zu Nabenmotoren, die in das Rad integriert sind, befinden sich Mid-Drive-Motoren am Tretlager und liefern die Energie direkt über den Antriebsstrang. Diese Anordnung verbessert die Effizienz, die Steigleistung und die Gewichtsverteilung und macht Mittelantriebsmotoren besonders attraktiv für Lastenfahrräder, E-Bikes für Pendler und leistungsstarke Offroad-Modelle.

Was ist ein Mid-Drive-Motor?

Ein Mid-Drive-Motor ist ein Elektromotor, der am Tretlager des Fahrrads montiert und direkt mit der Kurbelgarnitur verbunden ist. Im Gegensatz zu Nabenmotoren, die das Rad unabhängig voneinander antreiben, übertragen Mid-Drive-Motoren die Kraft über den Ketten- oder Riemenantrieb des Fahrrads und ermöglichen es dem Fahrer, das Getriebesystem für optimale Leistung zu nutzen. Diese Konfiguration ermöglicht im Vergleich zu Nabenmotoren ein höheres Drehmoment, eine effizientere Kraftnutzung und ein natürlicheres Pedaliergefühl.

Einer der Hauptvorteile von Motoren mit mittlerem Antrieb ist ihre Fähigkeit, die Leistungsabgabe je nach Gangschaltung des Fahrrads zu optimieren. Beim Bergauffahren kann ein Mittelmotor beispielsweise niedrigere Gänge nutzen, um das Drehmoment zu erhöhen und so die Belastung von Motor und Akku zu verringern. Das macht Mid-Drive-Systeme weitaus effizienter als Nabenmotoren, die aufgrund ihrer festen Übersetzung in steilem Gelände oft härter arbeiten müssen. Außerdem bieten Mid-Drive-Motoren eine bessere Gewichtsverteilung, da die schwersten Komponenten - Akku und Motor - mittig angeordnet sind, was die Balance und das Handling verbessert.

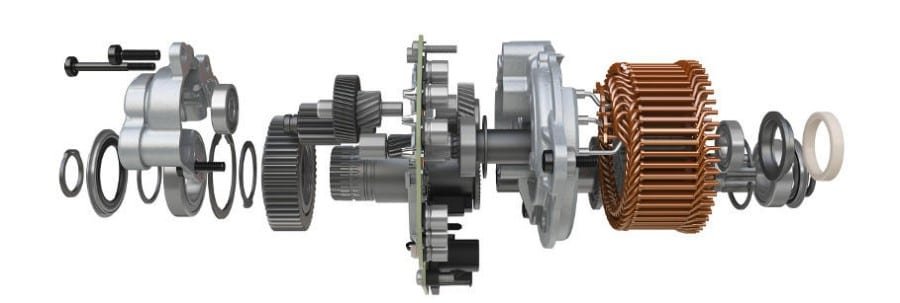

Zu den wichtigsten Komponenten eines Mittelmotors gehören:

- Motorgehäuse: Die Hauptantriebsquelle, in der Regel ein bürstenloser Gleichstrommotor, der elektrische Energie in mechanische Kraft umwandelt.

- Übertragungssystem: Er ist für die Übertragung der Motorkraft auf die Kurbel und anschließend auf den Antriebsstrang verantwortlich und sorgt für eine effiziente Drehmomentübertragung.

- Sensorisches System: Hochpräzise Sensoren, wie Drehmoment- und Trittfrequenzsensoren, überwachen kontinuierlich die Tretkraft des Fahrers und passen die Unterstützung des Motors entsprechend an.

- Steuereinheit: Diese auch als Motorsteuerung bezeichnete Komponente verarbeitet Echtzeitdaten von den Sensoren, um die Leistungsabgabe zu regulieren und ein reibungsloses und intuitives Fahrerlebnis zu gewährleisten.

Führende Hersteller wie Bosch, Shimano und Bafang haben diese Komponenten weiter verfeinert, um die Effizienz zu steigern und eine bessere Integration in moderne E-Bike-Systeme zu gewährleisten.

Funktionsprinzipien: Die Funktionsweise eines Mid-Drive-Motors

Die Funktionsweise eines Mid-Drive-Motors konzentriert sich auf DrehmomentsensorikDadurch kann der Motor eine natürliche, reaktionsschnelle Unterstützung bieten, die sich den Eingaben des Fahrers anpasst. Drehmomentsensoren erkennen die auf die Pedale ausgeübte Kraft und passen die Motorleistung in Echtzeit an, um eine proportionale Reaktion zu gewährleisten, die das Gefühl des traditionellen Radfahrens nachahmt. So entsteht ein nahtloses und intuitives Erlebnis, bei dem der Motor die Anstrengung des Fahrers verstärkt und je nach Tretintensität genau das richtige Maß an Unterstützung bietet.

Einer der wesentlichen Vorteile von Motoren mit Mittelmotorantrieb ist die Gleichmäßigkeit der Leistungsabgabe. Im Gegensatz zu Nabenmotoren, die manchmal einen Leistungssprung erzeugen können, bieten Mid-Drive-Systeme eine linearere und kontrolliertere Leistung. Dies gewährleistet dem Fahrer eine gleichmäßige Beschleunigung und eine bessere Stabilität, insbesondere bei Steigungen oder in unebenem Gelände. Außerdem können Mid-Drive-Motoren das vorhandene Getriebesystem des Fahrrads nutzen, so dass der Motor effizienter arbeiten kann, indem er die optimale Drehzahl bei verschiedenen Geschwindigkeiten und Belastungen beibehält.

Der Stromübertragungsweg in einem Mid-Drive-System ist im Vergleich zu Nabenmotoren auch effizienter. Da die Kraft des Motors direkt über die Kurbel und die Kette übertragen wird, nutzt er den mechanischen Vorteil, den die Schaltung des Fahrrads bietet. Dadurch wird nicht nur die Effizienz des Motors verbessert, sondern auch die Belastung des Systems verringert und die Lebensdauer von Motor und Antriebskomponenten verlängert.

Studien, die von Bericht über Elektrofahrräder (2023) haben gezeigt, dass Motoren mit Mittelmotorantrieb bis zu 25% mehr Effizienz im Vergleich zu Nabenmotoren, wenn es bergauf geht oder schwere Lasten getragen werden, was ihre Überlegenheit unter anspruchsvollen Bedingungen unterstreicht. Es wird erwartet, dass Mittelmotoren bei der Weiterentwicklung der E-Bike-Industrie eine entscheidende Rolle bei der Verbesserung der Leistung und Zuverlässigkeit von Elektrofahrrädern spielen werden.

- Weiterführende Literatur: Cargo Bike Markttrend 2025

Hauptmerkmale von Mid-Drive-Motoren

- Drehmomentsensorgestützte Tretunterstützung: Mid-Drive-Motoren verwenden in der Regel Drehmomentsensoren, um die Leistungsabgabe an die Tretkraft des Fahrers anzupassen und so ein natürliches und reaktionsschnelles Fahrgefühl zu vermitteln.

- Hohe Drehmomentleistung: Die Mittelmotoren erzeugen ein hohes Drehmoment, das für das Erklimmen von Hügeln und das Tragen schwerer Lasten unerlässlich ist.

- Integration in den Antriebsstrang: Mittelmotoren arbeiten über die vorhandenen Gänge des Fahrrads und ermöglichen so eine effizientere Energienutzung.

- Kompaktes und ausgewogenes Design: Die in der Mitte des Motorrads angeordneten Mittelmotoren sorgen für eine bessere Gewichtsverteilung und ein besseres Handling.

- Effiziente Nutzung der Batterie: Mid-Drive-Motoren optimieren den Batterieverbrauch, indem sie das Übersetzungsverhältnis nutzen, um die Belastung des Motors zu verringern.

Mid-Drive-Motoren vs. Nabenmotoren

Um zu verstehen, warum Mid-Drive-Motoren in Cargo-E-Bikes bevorzugt werden, sollten wir sie mit Nabenmotoren vergleichen:

| Besonderheit | Mittelmotor | Nabenmotor |

| Platzierung | Tretlager | Radnabe |

| Effizienz | Hoch aufgrund der Nutzung des Getriebes | Niedrigeres, konstantes Ausgangsdrehmoment |

| Drehmoment Leistung | Höher, besser bergauf | Niedriger, kämpft mit schweren Lasten |

| Gewichtsverteilung | Zentriert, ausgeglichen | Unwucht, beeinträchtigt die Handhabung |

| Wartung | Komplexer, erfordert Wartung des Antriebsstrangs | Einfacher, aber schwieriger zu ersetzen |

| Idealer Anwendungsfall | Cargo-E-Bikes, Mountain-E-Bikes | Pendler- und preisgünstige E-Bikes |

Weiterführende Literatur:

Die Entwicklung der Mid-Drive-Motortechnologie

Motoren mit Mittelantrieb haben in den letzten zehn Jahren erhebliche technische Fortschritte gemacht. Frühe Modelle waren sperrig, teuer und mechanisch komplex, was ihre Verbreitung einschränkte. Jüngste Innovationen bei Drehmomentsensoren, Leistungsmanagement und Motoreffizienz haben jedoch zu kompakteren, leichteren und energieeffizienteren Designs geführt.

Regen 02 E-Lastenrad

Suchen Sie nach einem kompakten, anpassbaren Frontlader für Ihre Marke?

TÜV-geprüft durch vergangene kundenspezifische Projekte. Öffentlich verfügbares Modell – konfigurierbar, bewährt und skalierbar.

Warum Mid-Drive-Motoren ideal sind für Fracht-E-Bikes

Cargo-E-Bikes sind für den Transport schwerer Lasten ausgelegt, sei es für kommerzielle Lieferungen oder für den persönlichen Transport. Hier erfahren Sie, warum Motoren mit Mittelantrieb die beste Wahl für Cargo-E-Bikes sind:

Verbessertes Drehmoment und Leistung

Mid-Drive-Motoren können die vorhandene Gangschaltung des Fahrrads nutzen, so dass der Fahrer das Übersetzungsverhältnis an die Fahrbedingungen anpassen kann. Diese Anpassungsfähigkeit führt zu einer effizienten Energienutzung und einer verbesserten Leistung, insbesondere beim Bergauffahren oder beim Tragen schwerer Lasten. Eine Studie, in der die Effizienz von Motoren mit Mittel- und Nabenantrieb verglichen wurde, ergab zum Beispiel, dass Motoren mit Mittelantrieb sind etwa 18% energieeffizienter als alternative Konzepte.

Weitere Lektüre :

2. Optimierte Gewichtsverteilung

Da die Motoren des Mittelantriebs in der Mitte des Fahrrads platziert sind, tragen sie zur Erhaltung des Gleichgewichts bei. Diese gleichmäßige Gewichtsverteilung verbessert das Handling und die Stabilität, was für Cargo-E-Bikes, die große oder schwere Gegenstände transportieren, entscheidend ist.

Weitere Lektüre :

3. Effiziente Nutzung der Batterieleistung

Durch die Nutzung des Getriebesystems des Fahrrads optimieren die Mid-Drive-Motoren den Stromverbrauch. Diese Effizienz verlängert die Lebensdauer des Akkus und ermöglicht es Cargo-E-Bikes, mit einer einzigen Ladung längere Strecken zurückzulegen, was sie für Liefer- und Transportanwendungen geeignet macht. Diese Effizienz führt zu längeren Fahrstrecken mit einer einzigen Ladung, was für Cargo-E-Bikes, die bei Lieferdiensten oder im Fernverkehr eingesetzt werden, unerlässlich ist. Die Forschung zeigt, dass Motoren mit Mittelantrieb im Vergleich zu Nabenmotoren eine höhere Energieeffizienz erreichen können, insbesondere in Szenarien, die ein hohes Drehmoment bei niedrigen Geschwindigkeiten erfordern.

4. Bessere Leistung bei Steigungen

Cargo-E-Bikes haben oft mit steilen Hängen zu kämpfen, besonders in städtischen Umgebungen. Ein Motor mit Mittelantrieb ermöglicht es dem Fahrer, zu schalten und ein optimales Drehmoment aufrechtzuerhalten, sodass Steigungen auch mit schwerer Ladung leichter zu bewältigen sind.

Dank der Fähigkeit, Gänge zu schalten, können die Motoren mit mittlerem Antrieb auch bei schwerer Ladung ein optimales Drehmoment und eine optimale Geschwindigkeit beibehalten, wenn es bergauf geht. Diese Fähigkeit stellt sicher, dass die Fahrer verschiedene Terrains bewältigen können, ohne die Geschwindigkeit oder die Lebensdauer der Batterie zu beeinträchtigen. Studien haben gezeigt, dass Motoren mit Mittelantrieb unter verschiedenen Bedingungen, insbesondere im Gelände, außergewöhnlich gut funktionieren.

5. Geringere Belastung der Räder

Nabenmotoren belasten die Räder zusätzlich, was zu Verschleiß führen kann, vor allem bei schweren Lasten. Mid-Drive-Motoren vermeiden dieses Problem, indem sie die Kraft über den Antriebsstrang übertragen, wodurch die Integrität der Räder erhalten bleibt und die Wartungskosten gesenkt werden.

Cargo Line Motor

Der Cargo Line Motor ist ein Hochleistungs-Mittelantriebssystem, das speziell für Cargo-E-Bikes entwickelt wurde und außergewöhnliche Leistung, Haltbarkeit und Effizienz für schwere Anwendungen bietet. Der von Bosch eBike Systems, einem weltweit führenden Anbieter von E-Bike-Technologie, entwickelte Cargo Line Motor ist für die Anforderungen der städtischen Logistik, kommerzieller Lieferungen und alltäglicher Transporte konzipiert. Als Premiumlösung bietet er ein ausgewogenes Verhältnis von hohem Drehmoment, intelligenter Leistungsverteilung und verstärkter Haltbarkeit, was ihn zur bevorzugten Wahl für Lastenradhersteller und professionelle Anwender macht.

Eines der herausragenden Merkmale des Cargo Line-Motors ist sein beeindruckendes Drehmoment, das typischerweise zwischen 85-95 Nm liegt und es dem Fahrer ermöglicht, schwere Lasten, steile Steigungen und den Stop-and-Go-Verkehr in der Stadt problemlos zu bewältigen. Sein intelligentes Power-Management-System passt die Motorunterstützung dynamisch an die Fahrbedingungen und das Gewicht der Nutzlast an und optimiert so die Energieeffizienz bei gleichmäßiger Beschleunigung. Darüber hinaus hat Bosch das Cargo Line System mit einer verbesserten Haltbarkeit des Antriebsstrangs ausgestattet, der verstärkte Komponenten enthält, die den erhöhten Belastungen beim Gütertransport standhalten, die Lebensdauer des Motors verlängern und den Wartungsbedarf reduzieren.

In der Praxis hat sich der Cargo Line-Motor als unschätzbarer Vorteil für die städtische Logistik und die Zustellung auf der letzten Meile erwiesen. Unternehmen wie DHL und UPS haben Cargo-E-Bikes in ihre Flotten integriert, um die Effizienz und Nachhaltigkeit zu verbessern. Das System wird auch häufig in Familien-Lastenrädern eingesetzt, mit denen Eltern mühelos Kinder und Lebensmittel transportieren können. Das Marktfeedback unterstreicht die gleichmäßige und kontrollierte Leistungsabgabe des Motors, seine Zuverlässigkeit bei schweren Lasten und seine Fähigkeit, die Akku-Reichweite deutlich zu erhöhen, und festigt seine Position als die beste Lösung für moderne Cargo-E-Bikes.

Aktuelle Anwendungen und Markttrends

Die Nachfrage nach Motoren mit mittlerem Antrieb ist in den letzten Jahren aufgrund ihrer überlegenen Drehmoment-Effizienz, ihres natürlichen Pedaliergefühls und ihrer Fähigkeit, verschiedene Terrains zu bewältigen, stark angestiegen. Während Nabenmotoren nach wie vor bei E-Bikes der Einstiegsklasse dominieren, werden Mittelantriebssysteme immer mehr zur bevorzugten Wahl für Premium-E-Bikes, Lastenräder und Off-Road-Anwendungen.

Europa, das bei der Einführung von E-Bikes führend ist, hat einen starken Anstieg der Integration von Motoren mit mittlerem Antrieb zu verzeichnen, wobei Deutschland, die Niederlande und Frankreich die wichtigsten Märkte sind. Nach Angaben der Confederation of the European Bicycle Industry (CONEBI) werden im Jahr 2022 über 60% der in Europa verkauften E-Bikes mit einem Mittelmotor ausgestattet sein. Dieser Trend wird durch die Vorliebe der Verbraucher für leistungsstarke Fahrräder mit elektrischer Unterstützung und staatliche Anreize zur Förderung der Elektromobilität angetrieben. In Nordamerika hat die wachsende Beliebtheit von E-Bikes der Klassen 1 und 3, die auf Tretunterstützung ohne Gashebel angewiesen sind, die Nachfrage nach Motoren mit Mittelantrieb weiter angeheizt.

Wie Sie den richtigen Mid-Drive-Motor für Ihr Cargo-E-Bike auswählen

Bei der Auswahl eines Mittelmotors für ein Cargo-E-Bike sollten Sie die folgenden Faktoren berücksichtigen:

- Drehmoment Leistung: Ein höheres Drehmoment (über 80 Nm) wird für den Transport schwerer Lasten empfohlen.

- Akku-Kompatibilität: Stellen Sie sicher, dass das Motorsystem mit Batterien mit hoher Kapazität (500Wh oder mehr) kompatibel ist, um die Reichweite zu erhöhen.

- Getriebesystem: Ein Motor mit mittlerem Antrieb funktioniert am besten mit einer robusten Schaltung, z. B. einer internen Nabenschaltung oder einer Kettenschaltung.

- Langlebigkeit und Verlässlichkeit: Wählen Sie einen Motor von renommierten Marken, die Garantien und Kundendienst anbieten.

- Kontrollsystem und intelligente Funktionen: Fortschrittliche Systeme mit Bluetooth-Konnektivität, integrierten Sensoren und anpassbaren Tretunterstützungsstufen sorgen für ein besseres Fahrerlebnis.

Wartungstipps für Mid-Drive-Motoren in Cargo-E-Bikes

Eine ordnungsgemäße Wartung gewährleistet die Langlebigkeit und Effizienz eines Mittelmotorensystems. Hier sind einige wichtige Tipps:

- Halten Sie die Kette und den Antriebsstrang sauber: Da Motoren mit mittlerem Antrieb auf die Kette des Fahrrads angewiesen sind, muss diese gut geschmiert und frei von Schmutz sein, um den Verschleiß zu verringern.

- Regelmäßige Kontrolle der Gänge: Häufiges Schalten unter Last kann die Zahnräder belasten. Prüfen Sie sie auf Verschleiß und ersetzen Sie sie bei Bedarf.

- Batteriezustand überwachen: Verwenden Sie das empfohlene Ladegerät und vermeiden Sie Tiefentladungen, um die Lebensdauer der Batterie zu verlängern.

- Firmware aktualisieren: Wenn Ihr Motorsystem Firmware-Updates unterstützt, sollten Sie es auf dem neuesten Stand halten, um eine optimale Leistung zu gewährleisten.

- Prüfen der Motorhalterungen und -anschlüsse: Erschütterungen durch die Ladung können Schrauben und elektrische Verbindungen lockern, daher sind regelmäßige Kontrollen unerlässlich.

Rechtliche Rahmenbedingungen und Nachhaltigkeitserwägungen

Auch die rechtlichen Rahmenbedingungen haben Einfluss auf die Einführung von Motoren mit mittlerem Antrieb. In Europa legt die Norm EN 15194 strenge Leistungs- und Sicherheitsstandards für Elektrofahrräder fest, die Einfluss auf die Konstruktion und Integration von Motoren haben. In den USA werden E-Bikes der Klassen 1 und 3 (mit Tretunterstützung ohne Gashebel) häufig mit Mittelmotoren ausgestattet, da sie den lokalen Vorschriften entsprechen.

Unter dem Gesichtspunkt der Nachhaltigkeit verbessern Mittelmotoren die Batterieleistung, senken den Energieverbrauch und verlängern die Lebensdauer der Batterien. Dies steht im Einklang mit dem Bestreben der Branche nach umweltfreundlicheren Transportlösungen und stärkt Mittelmotoren als Schlüsselkomponente für nachhaltige urbane Mobilität.

Zukunftstrends und Branchenausblick

Die Zukunft der Mittelmotoren ist geprägt von Fortschritten in den Bereichen KI, IoT-Konnektivität und nachhaltige Materialien. Zu den aufkommenden Trends gehören:

- KI-gestützte intelligente Assistenz: Die dynamische Anpassung des Drehmoments an das Gelände und das Verhalten des Fahrers verbessert die Effizienz und das Fahrerlebnis.

- Leichte und kompakte Designs: Die Miniaturisierung von Motoren ohne Leistungseinbußen wird die Gesamtleistung von E-Bikes verbessern.

- Nachhaltigkeit und umweltfreundliche Produktion: Die Verwendung von wiederverwertbaren Materialien und eine energieeffiziente Produktion tragen zu einer geringeren CO2-Bilanz bei.

- Expandierende Marktnachfrage: Das Wachstum in Asien und Nordamerika, das durch die Urbanisierung und staatliche Anreize angeheizt wird, wird die Einführung von Motoren mit mittlerem Antrieb weiter vorantreiben.

Abschluss

Mid-Drive-Motoren definieren die Leistung von E-Bikes neu. Sie bieten überlegene Effizienz, verbesserte Fahrdynamik und Vielseitigkeit in verschiedenen Anwendungsbereichen. Während Nabenmotoren für preisgünstige Modelle nach wie vor beliebt sind, treibt die Verlagerung der Branche hin zu Hochleistungs-E-Bikes die Innovation in der Mittelantriebstechnologie voran. Für Unternehmen, die hochmoderne E-Bike-Lösungen integrieren möchten, bieten Mittelantriebsmotoren eine unübertroffene Kombination aus Leistung, Effizienz und Anpassungsfähigkeit. Im Zuge des technologischen Fortschritts wird die Zukunft der E-Bikes zweifellos von intelligenteren, effizienteren Mittelantriebssystemen angetrieben werden.

Quellen:

- Fortune Business Insights, 2023

- Confederation of the European Bicycle Industry (CONEBI), 2023

- Bosch eBike Systems Technische Dokumentation, 2023

- Shimano STEPS EP8 Produktblatt, 2023

- Bafang M620 Technische Daten, 2023

- Yamaha PWseries ST Produktübersicht, 2023

- Brose Drive S Mag Produktdokumentation, 2023