La pintura no sólo sirve para que una bicicleta de carga tenga un aspecto atractivo: es la primera línea de defensa contra la corrosión, los arañazos y la degradación medioambiental. En Regen, donde nos encargamos de todo, desde la fabricación del cuadro hasta el revestimiento final, a menudo nos preguntan: ¿cuánto dura la pintura del cuadro de la bicicleta? Nosotros somos fabricante de bicicletas de carga personalizadas con más de 10 años de experiencia en el sector de las bicicletas eléctricas.

Si es nuevo en los sistemas de pintura o está explorando diferentes técnicas de recubrimiento, le recomendamos que empiece con nuestro Guía definitiva para pintar cuadros de bicicleta - una visión completa de los tipos de pintura, la preparación de superficies, las técnicas y las situaciones de aplicación más comunes.

La respuesta no es única. Dependiendo del método de recubrimiento, la preparación del material, el entorno de uso y los hábitos de mantenimiento, la durabilidad de la pintura puede oscilar entre unos pocos años y más de una década. En esta guía, desglosaremos los factores clave que influyen en la vida útil de la pintura, compararemos diferentes tecnologías de pintura y ofreceremos consejos prácticos para garantizar que sus bicicletas de carga mantengan su acabado profesional a largo plazo.

Por qué es importante la durabilidad de la pintura del cuadro

La durabilidad de la pintura es más que una cuestión estética:

- Protección: Evita la oxidación, la corrosión y la entrada de agua, especialmente en marcos de aluminio o acero.

- Imagen de marca: Los marcos descoloridos o desconchados pueden socavar la calidad percibida de su flota o producto.

- Valor de reventa: Los acabados en buen estado mejoran la viabilidad de reventa o alquiler de las bicicletas eléctricas y de carga.

- Conformidad: En algunos mercados de la UE, la integridad de la pintura está vinculada a los requisitos de inspección visual de las normas de seguridad (por ejemplo, la norma EN 17860 para bicicletas de carga).

Vida útil típica de la pintura de cuadros de bicicleta

| Tipo de revestimiento | Vida útil prevista | Casos de uso típicos |

|---|---|---|

| Pintura líquida (acrílico/PU) | 3-5 años | Cuadros básicos, bicicletas urbanas |

| Recubrimiento en polvo (estándar) | 5-7 años | Bicicletas de carga OEMflotas comerciales |

| Recubrimiento en polvo + ED (doble) | 8-10+ años | Bicicletas eléctricas de carga premium, uso en condiciones de alta humedad |

| Anodizado (sólo aluminio) | Más de 10 años | Bicicletas ultraligeras o sensibles a la corrosión |

| Metal en bruto + revestimiento transparente | 2-3 años | Modelos estéticos de nicho |

Nota: La vida útil se basa en un uso medio en exteriores, con una exposición moderada a la intemperie y un mantenimiento estándar.

6 factores clave que afectan a la longevidad de la pintura

1. Calidad de la preparación de la superficie

Antes de aplicar cualquier pintura, las superficies del bastidor deben limpiarse, desengrasarse y tratarse adecuadamente.

- Granallado o decapado ácido elimina los residuos y da rugosidad a la superficie para mejorar la adherencia.

- Pretratamiento como el recubrimiento de fosfato o ED (deposición electroforética) crea una capa inferior resistente a la corrosión.

📌 En Regen, utilizamos Recubrimiento ED + recubrimiento en polvo como nuestro estándar para los modelos de exportación, creando un sistema de doble barrera que resiste tanto la abrasión mecánica como la corrosión química.

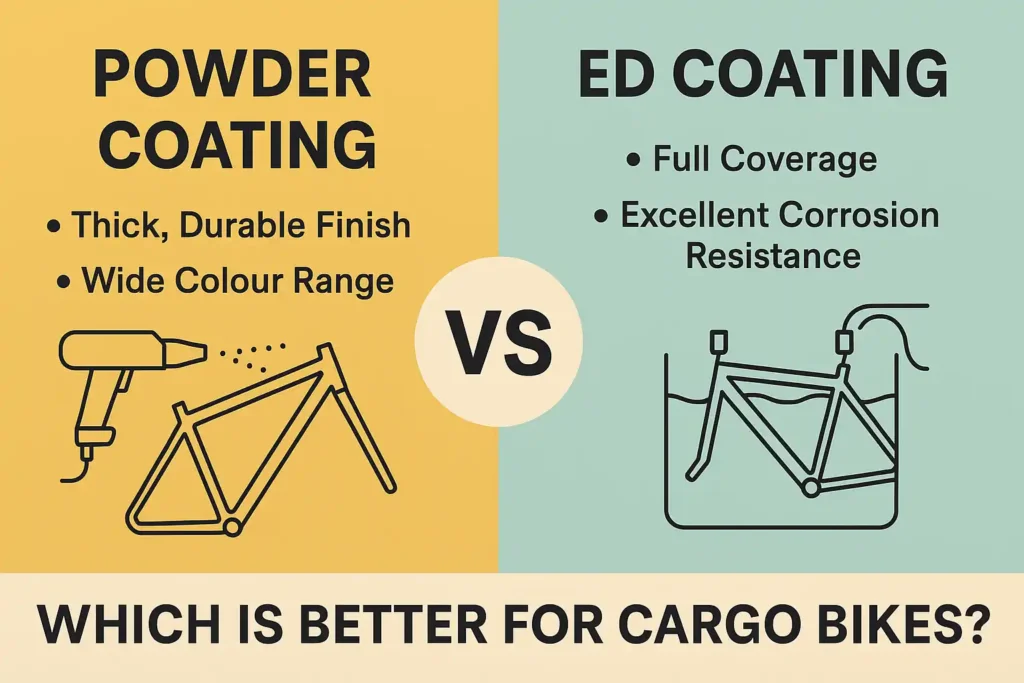

Lecturas relacionadas: Recubrimiento Ed vs. Recubrimiento en polvo

2. Tipo de pintura y método de aplicación

- Pintura líquida (pulverizada) puede ofrecer colores vivos, pero es más propenso al desconchado y a la degradación por los rayos UV.

- Recubrimiento en polvo se hornea a 180-200°C, formando una capa duradera y uniforme. Es más gruesa (60-100μm) y más resistente a los arañazos.

- Sistemas bicapa (ED + polvo) prolongan considerablemente la durabilidad, especialmente en entornos costeros o urbanos.

Cuadro comparativo

| Atributo | Pintura líquida | Pintura en polvo | ED + Polvo |

|---|---|---|---|

| Resistencia UV | Medio | Alto | Alto |

| Protección contra la corrosión | Bajo | Bien | Excelente |

| Resistencia a los arañazos | Bajo-Medio | Alto | Muy alta |

| Costo | Bajo | Medio | Alto |

3. 3. Condiciones medioambientales

- Luz solar (UV): Provoca la decoloración y descomposición de ciertos pigmentos, especialmente en los revestimientos de baja calidad.

- Humedad y aire salado: Acelera la corrosión, sobre todo en ciudades costeras.

- Sales de carretera: En climas invernales, la niebla salina puede corroer rápidamente los marcos mal protegidos.

En regiones como el norte de Europa, donde la logística invernal es habitual, es esencial contar con sistemas de revestimiento resistentes.

4. Frecuencia y tipo de uso

- Bicicletas de reparto de alto kilometraje enfrentarse a más restos de la carretera, rozaduras de aparcamiento y contacto de carga y descarga.

- Flotas de alquiler pueden sufrir un desgaste más rápido debido a los múltiples usuarios y a un menor cuidado.

- Uso privado en condiciones suaves tiende a ver una mayor duración de la pintura.

5. Material del marco

El material de base afecta a la adherencia de la pintura y a la preparación que requiere:

| Material | Adherencia de la pintura | Notas |

|---|---|---|

| Aluminio (6061) | Bien | Requiere un tratamiento previo especial; no se oxida de forma natural |

| Acero (Hi-Ten) | Excelente | Acepta fácilmente el revestimiento, pero se oxida si se astilla |

| Acero inoxidable | Moderado | Difícil de recubrir; a menudo se deja sin pintar o se recubre con imprimación. |

| Fibra de carbono | Feria | Requiere resinas especiales y un cuidadoso control de la temperatura |

6. Hábitos de mantenimiento

- Lavado regular con jabón suave elimina la suciedad y la sal.

- Evitar las mangueras de alta presión cerca de las costuras evita la intrusión de agua.

- Pintura de retoque en pequeñas virutas puede evitar la corrosión bajo la película.

Signos de que la pintura del cuadro de tu bicicleta se está desgastando

- Tiza: Superficie descolorida o pulverulenta debido a daños causados por los rayos UV.

- Descamación: A menudo debido a una mala preparación o a la humedad bajo la pintura.

- Óxido o burbujas: Indica corrosión bajo la capa de pintura.

- Decoloración: Especialmente en colores rojos, amarillos o fluorescentes con escasa protección UV.

Los primeros signos de desgaste pueden tratarse a menudo con tratamientos puntuales; los tratamientos completos sólo son necesarios cuando la protección estructural se ve comprometida.

Cómo prolongar la vida útil de la pintura del cuadro de la bicicleta

- Elija el sistema de pintura adecuado para su caso de uso - en Regen, recomendamos ED + polvo para uso comercial o de alquiler a largo plazo.

- Guardar las bicicletas a cubierto o en el interior cuando sea posible.

- Realizar inspecciones periódicas - especialmente en las juntas de soldadura y los bordes del bastidor.

- Educar a los usuarios finales (propietarios de flotas, familias) sobre la limpieza adecuada y la reparación de desconchones.

Ejemplo de aplicación real: Sistema de doble revestimiento de Regen

Todos nuestros bastidores de carga de alta gama se someten a:

- Deposición electroforética (ED) para una resistencia a la corrosión de cobertura total, incluso en tubos ciegos y cordones de soldadura.

- Recubrimiento en polvo a alta temperatura (80-100μm) para un acabado exterior estable a los rayos UV y resistente a la abrasión.

Este sistema cumple con:

- ISO 9227 (pruebas de niebla salina)

- EN 15194 y EN 17860 para la seguridad de las bicicletas eléctricas y de carga

Es el mismo nivel de durabilidad que exigen las flotas postales europeas y los operadores de reparto de alimentos, demostrado a lo largo de años de uso intensivo.

Conclusión: La pintura es protección, no sólo estética

La durabilidad de la pintura no depende sólo de la elección del color. Refleja una combinación de decisiones de ingeniería, ciencia de las superficies y hábitos de los usuarios. En Regen, tratamos la pintura como una capa estructural de protección, no como una ocurrencia tardía.

Tanto si está planificando un nuevo pedido de OEM como si está evaluando el estado de su flota, conocer la vida útil de los recubrimientos de cuadros de bicicleta le ayudará a tomar decisiones más inteligentes y a mantener el mejor aspecto y rendimiento de sus bicicletas durante años.

📩 ¿Necesita ayuda con la selección o personalización del revestimiento?

Nuestro equipo de ingeniería está a su disposición para ayudarle en su estrategia de producto, desde el ajuste RAL hasta las soluciones validadas por niebla salina. Contáctanos para una consulta.

Lista de referencias

- ISO 9227:2017 - Ensayos de corrosión en atmósferas artificiales - Ensayos de niebla salina.

- ES 17860-1:2022 - Bicicletas - Bicicletas de carga - Requisitos de seguridad y métodos de ensayo.

- ASTM D3359 - Métodos de ensayo normalizados para la evaluación de la adherencia mediante ensayo con cinta adhesiva.

- Davis, J. R. (2000). Corrosión: Conceptos básicos. ASM Internacional.

- Federación Europea de Recubrimiento en Polvo. (2023). Manual de recubrimiento en polvo.