Como Regen, recebemos frequentemente perguntas de clientes e parceiros sobre sensores de binário - o que são, como funcionam e porque são tão importantes nas e-bikes e bicicletas de carga. Os sensores de binário são um daqueles componentes ocultos que podem não ser notados à primeira vista, mas que moldam fundamentalmente a experiência de condução, a eficiência do motor e até a segurança das bicicletas com assistência eléctrica.

Neste artigo, vamos explorar os sensores de binário em pormenor: o que fazem, como funcionam, as suas vantagens e desvantagens e onde são utilizados. Também relacionaremos o seu papel com considerações de conceção de bicicletas de carga mais amplas, tais como a seleção do binário do motor e os protocolos de comunicação no sistema elétrico.

O que é um sensor de binário?

Um sensor de binário é um dispositivo que mede a quantidade de binário (força de rotação) aplicada a um eixo ou a um eixo. Numa bicicleta eléctrica ou de carga, está normalmente localizado no suporte inferior, dropout traseiro ou eixo da manivela. Quando um ciclista exerce pressão sobre os pedais, o sensor de binário detecta a força de torção e envia um sinal ao controlador do motor. O controlador ajusta então a assistência do motor de forma proporcional.

Isto difere significativamente de sensores de cadênciaque detectam simplesmente se está a pedalar ou não, sem medir a força com que está a pedalar. Enquanto os sensores de cadência tendem a proporcionar uma sensação de assistência mais binária, "on/off", os sensores de binário permitem uma experiência de pedalagem mais suave e natural.

Definição:

Binário = Força × Distância (medida em Newton-metros, Nm).

Se aplicarmos 100 N de força num braço de manivela de 0,17 m, o binário resultante é de 17 Nm.

2. Como é que os sensores de binário funcionam?

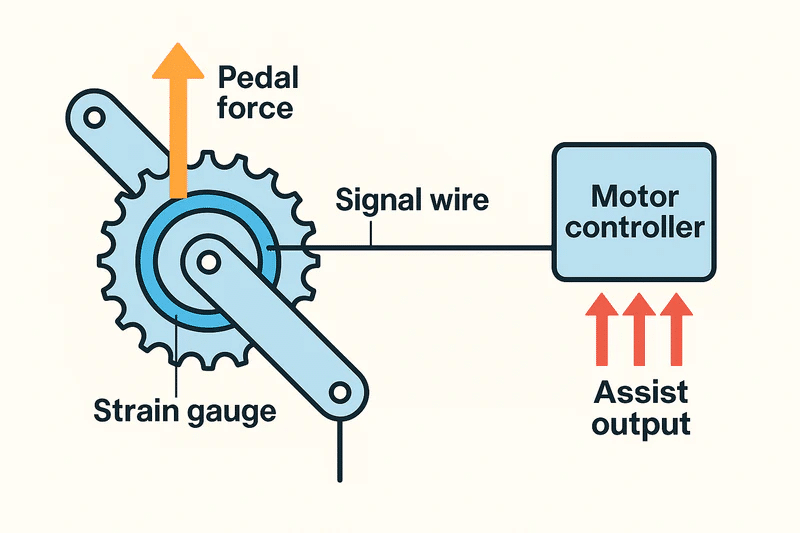

A maioria dos sensores de binário utilizados em bicicletas eléctricas e bicicletas de carga são com base em extensómetros. Vamos decompor o princípio de funcionamento:

2.1 Método do extensómetro

- A árvore ou eixo da manivela torce-se ligeiramente quando o ciclista pedala.

- Medidores de tensão-pequenos elementos resistivos eléctricos-estão ligados ao eixo.

- À medida que o fuso se deforma, os extensómetros mudam de resistência.

- Estas alterações são amplificadas através de um circuito de ponte de Wheatstone e convertidas num sinal elétrico.

- O controlador do motor interpreta este sinal como o esforço de entrada do ciclista e ajusta a potência de saída em conformidade.

2.2 Método Magnetoelástico

Alguns sensores de binário topo de gama utilizam princípios magnetoelásticos:

- O aço do fuso altera a sua permeabilidade magnética quando está sob torção.

- Os sensores de campo magnético detectam estas alterações sem contacto físico.

- A vantagem: menos desgasteA utilização de um sistema de controlo de qualidade é muito simples, uma vez que não existem fios ou anéis colectores nas partes móveis.

Diagrama de um sensor de binário de uma bicicleta eléctrica

Sensor de binário vs. sensor de velocidade: qual é o melhor?

Em termos simples, trata-se de um condutor experiente contra um condutor aprendiz

Pode utilizar-se a analogia entre um condutor experiente e um aprendiz de condutor:

O sensor de binário é como um "condutor experiente"

- O condutor experiente controlará suavemente a potência do veículo de acordo com as condições da estrada e a força do acelerador:

- Em caso de subida, o acelerador será automaticamente aumentado (maior assistência do motor).

- Em descidas ou com uma ligeira pressão no acelerador, a potência será reduzida (poupança de energia e segurança).

- Toda a experiência de condução é suave e natural, e a sensação de segurança é forte.

O sensor de velocidade é como um "aprendiz de condutor"

- O aprendiz de motorista apenas tem uma noção geral do interrutor do acelerador:

- Assim que o acelerador é premido, é dado todo o gás, independentemente das condições da estrada.

- A reação é lenta e o acelerador está totalmente aberto ou fechado.

- É fácil ter acelerações e desacelerações bruscas durante a condução, especialmente quando se está carregado. Não é seguro.

Resumo: Sensor de binário = saída inteligente a pedido, sensor de velocidade = saída fixa (pára se ninguém estiver a premir, potência máxima se estiver a premir)

Sensores de binário (baseados na força do pedal)

- Medida a intensidade com que está a pedalar detectando a força de rotação aplicada à manivela, ao suporte inferior ou ao dropout traseiro.

- A assistência é proporcionalQuanto mais se pedala, mais potência o motor fornece.

Sensores de velocidade ou cadência (com base na velocidade do pedal)

- Medida se e a que velocidade está a pedalar utilizando ímanes e um sensor na manivela.

- A assistência é binário/on-off: quando se começa a pedalar e se atinge uma cadência definida, o motor entra em ação com uma potência pré-definida (não proporcional à força).

Quadro das principais diferenças num relance

| Recurso | Sensor de torque | Sensor de velocidade |

|---|---|---|

| Resposta do motor | Proporcional à força do pedal (natural e suave) | Potência de saída fixa quando o limite de cadência é atingido |

| Sensação de condução | A sensação de um esforço humano amplificado ("pernas biónicas") | Pode parecer brusco ou repentino; menos intuitivo |

| Eficiência da bateria | Superior: utiliza apenas o que é necessário | Inferior: pode, por vezes, desperdiçar energia |

| Custo | Superior (tecnologia mais complexa) | Inferior (simples, barato) |

| Configuração | Requer uma instalação e calibração precisas | Muito fácil de instalar e substituir |

| Melhor para | Bicicletas eléctricas de alta qualidade, bicicletas de carga, terrenos acidentados ou urbanos | Bicicletas eléctricas de entrada, terreno plano, condução casual |

Qual é o melhor para bicicletas de carga?

Para bicicletas de carga, sensores de binário são quase sempre a melhor escolha:

- Fornecimento de energia suave: Quando transporta crianças ou mercadorias, necessita de estabilidade nos arranques e paragens. Os sensores de binário proporcionam uma assistência previsível e proporcional.

- Eficiência da bateria: As frotas de distribuição e logística beneficiam de uma maior autonomia por carga.

- Controlo nas colinas: Os sensores de binário facilitam os arranques em subidas porque o motor responde instantaneamente à força exercida.

- Segurança: Os picos repentinos de energia dos sensores de velocidade podem causar oscilações ou mesmo tombamentos em bicicletas muito carregadas.

(Pode ler o nosso artigo sobre Qual é o binário necessário para a sua bicicleta de carga? para ver como os sensores de binário estão ligados à seleção do motor).

3. Vantagens dos sensores de binário nas bicicletas eléctricas e bicicletas de carga

3.1 Experiência de equitação natural

Como a assistência do motor é proporcional à força com que pedala, sente-se como se tivesse "pernas biónicas". A bicicleta responde intuitivamente aos seus comandos, o que é especialmente importante para bicicletas de carga que transportam cargas pesadas. Os condutores sentem-se mais em controlo a baixas velocidades, ao contornar obstáculos ou ao arrancar em subidas com crianças ou mercadorias a bordo.

3.2 Utilização eficiente da bateria

Os sensores de binário permitem ao controlador afinar a saída do motor:

- Se pedalar com mais força, o motor fornece mais potência.

- Se abrandar, o motor reduz a assistência. Esta resposta dinâmica ajuda a conservar a energia da bateria em comparação com os sistemas baseados na cadência, em que o motor pode, por vezes, fornecer potência desnecessária.

3.3 Melhoria da segurança

Nas bicicletas de carga, os picos repentinos de potência podem ser perigosos, especialmente quando estão totalmente carregadas. Os sensores de binário evitam a aceleração abrupta, fazendo corresponder a potência do motor ao esforço do condutor. Isto torna os arranques e paragens mais suaves e ajuda a manter a estabilidade.

3.4 Compatibilidade com controladores modernos

Os sensores de binário integram-se bem com Barramento CAN ou outros protocolos de comunicação utilizados nos sistemas eléctricos das bicicletas eléctricas. Os dados que fornecem podem ser partilhados com outros componentes, como unidades de visualização e sistemas de gestão de baterias, para um desempenho optimizado.

4. Desvantagens e considerações

Embora os sensores de binário tragam muitos benefícios, também têm alguns inconvenientes que vale a pena referir:

- Custo mais elevado: Em comparação com os sensores de cadência simples, os sensores de binário são mais caros devido à sua complexidade.

- Requisitos de calibração: Devem ser calibrados com precisão para garantir leituras exactas.

- Sensibilidade: Uma vez que medem micro-deflexões, as vibrações externas e as alterações de temperatura podem afetar o desempenho se não forem compensadas.

- Potencial de desgaste (tipos de extensómetros): Com o tempo, as tensões mecânicas podem degradar os sensores baseados em strain gauge, embora isso seja raro com componentes de qualidade.

Para os fabricantes de bicicletas de carga OEM/ODM como nós, estes factores têm de ser considerados durante o desenvolvimento do produto. Por exemplo, seleccionamos cuidadosamente conjuntos de suporte inferior que combinam durabilidade com deteção precisa de binário.

5. Aplicações dos sensores de binário

Os sensores de binário são utilizados numa grande variedade de indústrias, mas o seu papel na bicicletas eléctricas e bicicletas de carga é particularmente transformador.

5.1 Sistemas de assistência aos pedais

- Os sensores de binário são a espinha dorsal do pedais de assistência (pedelec) funcionalidade.

- Asseguram que a assistência eléctrica seja natural e proporcional.

5.2 Bicicletas de carga pesadas

- Para as bicicletas de carga do tipo Long John, Longtail e trike, o feedback preciso do binário é essencial para a estabilidade e confiança do condutor.

- Os passageiros transportam frequentemente crianças, compras ou bens comerciais; por conseguinte, um apoio motor previsível aumenta a segurança.

5.3 Frota e bicicletas de entrega

- As empresas de logística confiam nos sensores de binário para reduzir a fadiga do condutor e assegurar um desempenho consistente em vários terrenos e condições de carga.

5.4 Outras aplicações de mobilidade eletrónica

- As scooters eléctricas e os ciclomotores utilizam sensores semelhantes para o controlo do acelerador e da travagem regenerativa.

(Também pode encontrar o nosso artigo sobre Mecanismos de direção Ackerman em bicicletas de carga relevante, uma vez que os sensores de binário e a geometria da direção trabalham em conjunto para proporcionar uma condução estável sob carga).

6. Comparação: Sensores de binário vs Sensores de cadência

| Recurso | Sensor de torque | Sensor de cadência |

|---|---|---|

| Resposta do motor | Proporcional, suave, natural | Ligado/desligado, binário, menos intuitivo |

| Eficiência da bateria | Elevado (optimizado com base no esforço do ciclista) | Inferior (pode desperdiçar energia) |

| Custo | Mais alto | Mais baixo |

| Preferido Para | Bicicletas de carga, bicicletas eléctricas premium, terrenos acidentados | Bicicletas eléctricas de entrada, terreno plano |

Veredicto: Para bicicletas de carga, os sensores de binário são quase sempre a melhor escolha, porque permitem arranques mais suaves e uma utilização mais eficiente da bateria ao transportar cargas.

7. Integração na conceção de bicicletas de carga

No Regen, integramos sensores de binário durante a fase de conceção do suporte inferior, tendo em conta factores como:

- Geometria do quadro: A rigidez à volta da área do suporte inferior afecta a precisão do sensor.

- Níveis de binário do motor: Combinamos sensores com motores de tração intermédia ou de cubo que variam entre 60-100 Nm para a maioria das bicicletas de carga.

- Arquitetura eléctrica: Os dados do sensor de binário são processados juntamente com as informações de velocidade, cadência e temperatura do motor através do bus CAN.

Também trabalhamos em estreita colaboração com as nossas equipas de engenharia e de design industrial para garantir que o conjunto do sensor de binário se mantém selado contra humidade e poeira (IP65 ou superior). Isto é crucial para as bicicletas utilizadas na logística urbana, onde a exposição à chuva e aos detritos é inevitável.

8. Conclusão

Os sensores de binário podem não ser visíveis à primeira vista, mas estão entre os componentes mais importantes das bicicletas eléctricas e bicicletas de carga modernas. Eles:

- Proporcionam uma experiência de condução mais natural e reactiva.

- Melhorar a eficiência da bateria.

- Aumenta a segurança, especialmente quando se transportam cargas pesadas.

À medida que desenvolvemos soluções personalizadas para bicicletas de carga para clientes OEM/ODM, os sensores de binário fazem sempre parte da discussão. Selecionar o tipo certo (strain gauge ou magnetoelástico), assegurar uma calibração adequada e integrá-lo com o resto do sistema elétrico são passos críticos para fornecer um produto de alta qualidade.

Se estiver a considerar um novo projeto de bicicleta de carga e quiser discutir os sensores de binário, a seleção do motor e a sensação geral de condução, a nossa equipa de engenharia e ID pode apoiá-lo. Oferecemos consultas gratuitas por vídeo, telefone ou correio eletrónico para o ajudar a tomar as decisões certas para o seu mercado-alvo.

No final

Quer saber mais sobre a integração de sensores de binário no seu próximo projeto de bicicleta de carga? Contate-nos para discutir as suas necessidades. A nossa equipa da Regen é especializada em Soluções OEM/ODM para bicicletas de cargadesde o desenvolvimento do quadro até à integração do sistema elétrico.