Elektrická nákladní kola se stávají nepostradatelnými v městské logistice, rodinné dopravě a doručování na poslední míli. Srdcem těchto robustních vozidel jsou dvě klíčové komponenty: motor a baterieSpolečně tvoří páteř síly, výkonu a vytrvalosti.

I když rám a příslušenství mohou upoutat pozornost, jde o zdraví... motor a baterie což určuje dlouhodobou použitelnost, spolehlivost a – co je nejdůležitější –bezpečnostStejně jako u každého stroje není pravidelná údržba jen osvědčeným postupem – je to nutnost. Bez ní mohou i ta nejlépe navržená nákladní elektrokola trpět sníženým výkonem, zkrácenou životností a neočekávanými poruchami.

Údržba motoru

1. Pravidelná kontrola a čištění

Přestože jsou elektromotory používané v nákladních elektrokolech obvykle uzavřené a navržené tak, aby odolávaly povětrnostním vlivům, nejsou zcela utěsněny před vlivy prostředí. Postupem času se kolem skříně motoru může hromadit prach, nečistoty, vlhkost a organické nečistoty, jako je listí nebo tráva, zejména pokud se na kole jezdí v proměnlivých podmínkách, jako jsou městské ulice, štěrkové cesty nebo deštivé prostředí.

Co zkontrolovat:

Vizuálně zkontrolujte vnější povrch skříně motoru, přičemž věnujte zvláštní pozornost chladicím žebrům, větracím otvorům (pokud jsou přítomny) a oblasti, kde kabeláž vystupuje z skříně. Hledejte nahromadění silničního prachu, písku, zaschlého bláta nebo organického materiálu. Tyto nečistoty mohou bránit odvodu tepla nebo způsobovat opotřebení třením o pohyblivé součásti.

Proč na tom záleží:

Bezkartáčové motory se pro efektivní provoz spoléhají na pasivní nebo aktivní chlazení. Když jsou chladicí povrchy izolovány nečistotami, motor si může déle udržet teplo. Přehřátí může spustit tepelné snížení výkonu, což je vestavěný ochranný mechanismus, který snižuje výkon, aby se zabránilo poškození. Podle příručky údržby FUCARE BIKE EU patří nadměrné znečištění a blokované proudění vzduchu mezi nejčastější příčiny snížení výkonu souvisejícího s teplem.

Co dělat:

K jemnému odstranění nečistot z okolí skříně motoru použijte kartáč s měkkými štětinami, hadřík z mikrovlákna nebo stlačený vzduch. Nepoužívejte vysokotlaké vodní zdroje ani parní čističe, protože by mohly protlačit vlhkost přes ochranná těsnění a do citlivých vnitřních součástí. Tuto kontrolu provádějte pravidelně, zejména po jízdě ve vlhkém nebo prašném prostředí.

2. Kontroly šroubů a spojek

Nákladní elektrokola jsou vystavena většímu strukturálnímu namáhání než standardní kola kvůli přidané hmotnosti nákladu a cestujících. Toto zvýšené zatížení se promítá do vyšší úrovně vibrací a ohybu rámu, což může časem ovlivnit uchycení motoru a elektrické připojení.

Co zkontrolovat:

Pravidelně kontrolujte šrouby upevňující motor k rámu – to je obzvláště důležité u motorů se středním pohonem, které jsou integrovány v oblasti středového složení a působí na ně přímý točivý moment při šlapání. Uvolněné šrouby mohou způsobit nesprávné vyrovnání nebo hluk a mohou ohrozit hnací ústrojí.

Zkontrolujte elektrické zapojení mezi motorem a regulátorem, zda nevykazuje známky opotřebení. Hledejte roztřepenou izolaci, korozi na konektorech, ohnuté kolíky nebo odkryté vodiče. Obzvláště citlivé jsou zóny s vysokými vibracemi v blízkosti řetězové vzpěry nebo zadní patky.

Co dělat:

Pomocí momentového klíče ověřte, zda jsou šrouby utaženy podle specifikací výrobce motoru – nadměrné utažení může poškodit závity, zatímco nedostatečné utažení může vést k pohybu a opotřebení. U elektrických konektorů odpojte a zkontrolujte kontakty, zda nejsou oxidovány nebo vlhké. V případě potřeby je očistěte čističem elektronických kontaktů a před opětovnou montáží se ujistěte, že je spojení pevné a správně usazené. Tyto kontroly by se měly provádět měsíčně nebo častěji při pravidelném a intenzivním používání.

Studie společnosti EBikeBC uvádí, že uvolněné úchyty motoru zvyšují hluk a míru opotřebení až o 30%.

3. Aktualizace softwaru a firmwaru

Moderní motory pro elektrokola se spoléhají na vestavěný software – firmware – v rámci svých elektronických řídicích jednotek, který řídí dodávku energie, interpretaci senzorů a komunikaci mezi komponenty, jako je baterie, ovladač a displej. Výrobci, včetně společností Bosch, Shimano, Brose a dalších, pravidelně vydávají aktualizace firmwaru, aby zlepšili výkon systému, řešili známé problémy a zajistili kompatibilitu s vyvíjejícím se hardwarem.

Proč aktualizovat:

Aktualizace firmwaru mohou výrazně zlepšit chování pohonného systému. Aktualizace mohou zahrnovat vylepšení citlivosti snímače točivého momentu, vylepšenou správu baterie nebo opravy chyb, které řeší občasné problémy, jako je zpožděná odezva napájení nebo nepřesné odhady dojezdu. V některých případech mohou aktualizace také vylepšit algoritmy pro správu teploty nebo umožnit kompatibilitu s novým příslušenstvím či aplikacemi.

Jak aktualizovat:

Postupy aktualizace se liší v závislosti na značce. Některé systémy umožňují aktualizace prostřednictvím doprovodné mobilní aplikace (např. Bosch eBike Flow, Shimano E-TUBE), zatímco jiné vyžadují připojení USB k notebooku nebo softwaru autorizovaného prodejce. Jezdci by se měli řídit pokyny výrobce a kontrolovat aktualizace alespoň jednou měsíčně. Používání zastaralého firmwaru může vést ke špatné odezvě točivého momentu, nesprávným údajům o stavu baterie nebo snížené celkové účinnosti – problémy, které jsou často chybně diagnostikovány jako selhání hardwaru.

4. Hydroizolace a ochrana proti vlhkosti

Přestože je většina motorů elektrokol konstruována s ohledem na odolnost vůči povětrnostním vlivům, včetně utěsněných pouzder a chráněných konektorů, nejsou zcela imunní vůči vniknutí vody nebo dlouhodobému vystavení vlhkosti. Pochopení stupně ochrany motoru proti vodě a preventivní péče jsou nezbytné pro udržení elektrické spolehlivosti.

Důležité je hodnocení IP:

Stupeň krytí (IP) udává, jak dobře zařízení odolává prachu a vodě. Motory s krytím IP65 nebo vyšším jsou považovány za odolné vůči nízkotlakým vodním paprskům a stříkající vodě z vozovky, takže jsou obecně bezpečné pro jízdu v dešti. I s vysokým krytím IP však může vystavení stojaté vodě, ponoření nebo dlouhodobá vlhkost časem vést ke korozi, zejména v blízkosti těsnění, konektorů nebo vnitřních ložisek.

Nejlepší postupy pro ochranu před vlhkostí:

- Nejezděte úmyslně hlubokou vodou ani neponořujte oblast motoru.

- Po jízdě za mokra jemně otřete kryt motoru suchým hadříkem, zejména v okolí vstupních bodů kabelů a montážních rozhraní.

- Nepoužívejte tlakové myčky ani vysokotlaké hadice, protože voda by mohla proniknout přes těsnění do vnitřních dutin.

- Kolo skladujte pokud možno na suchém a větraném místě.

Testování ze zdrojů, jako je např. Blog výzvy Marshmallow ukázaly, že i u motorů s utěsněnými náboji, které byly dlouhodobě vystaveny vlhkým podmínkám, se projevily známky vnitřní koroze, což zdůrazňuje důležitost sušení po jízdě a pravidelné kontroly. Správné řízení vlhkosti pomáhá prodloužit životnost motoru a udržovat elektrický výkon.

Údržba baterie

1. Návyky nabíjení

Lithium-iontové baterie se široce používají v nákladních elektrokolech díky své vysoké energetické hustotě, nízké hmotnosti a účinnosti dobíjení. Tyto baterie jsou však také citlivé na vzorce nabíjení a nesprávné používání může časem výrazně zkrátit jejich životnost nebo vést k problémům s výkonem.

Doporučené postupy:

- Použijte originální nabíječku dodávané výrobcem. Nabíječky jsou kalibrovány tak, aby odpovídaly specifickým protokolům řízení napětí a teploty systému správy baterií (BMS). Používání nabíječek třetích stran riskuje nesoulad napětí, nesprávné prahové hodnoty vypnutí nebo přehřátí.

- Jakmile je baterie plně nabitá, odpojte nabíječku. Ponechání baterie připojené přes noc nebo po delší dobu může zatěžovat články, zejména pokud je po delší dobu nabitá na úrovni 100% nebo blízko ní.

- Dobijte baterii, když dosáhne kapacity 20–30%. Vyhněte se pravidelnému vybíjení baterie na úroveň 0%, protože cykly hlubokého vybíjení zvyšují chemické namáhání a zkracují celkovou životnost baterie.

Praktiky, kterým se vyhnout:

- Nenabíjejte ihned po jízdě Pokud je baterie stále teplá. Před připojením k nabíječce ji nechte vychladnout na pokojovou teplotu.

- Neskladujte baterii v plně nabitém stavu po dobu delší než několik dní, zejména v teplém prostředí.

Podle pokynů společnosti Velotric pro péči o baterie může dodržování přiměřených nabíjecích cyklů a vyhýbání se přebíjení prodloužit životnost baterie o 25–40%.

2. Teplota a skladování

Teplota hraje klíčovou roli ve stavu a výkonu lithium-iontových baterií. Vystavení extrémnímu horku nebo chladu může urychlit degradaci článků, snížit kapacitu nebo způsobit dočasné vypnutí systému správy baterie z bezpečnostních důvodů.

Vyhněte se následujícím podmínkám:

- Vysoká teplota: Teploty nad 40 °C (104 °F) mohou vést k trvalé ztrátě kapacity a zvýšit riziko tepelného úniku ve špatně řízených systémech.

- Teploty mrazu: Nabíjení nebo skladování při teplotě pod 0 °C (32 °F) může způsobit lithiové pokovení anody, což poškozuje vnitřní strukturu článku a snižuje akceptaci nabíjení.

Pokyny pro správné skladování:

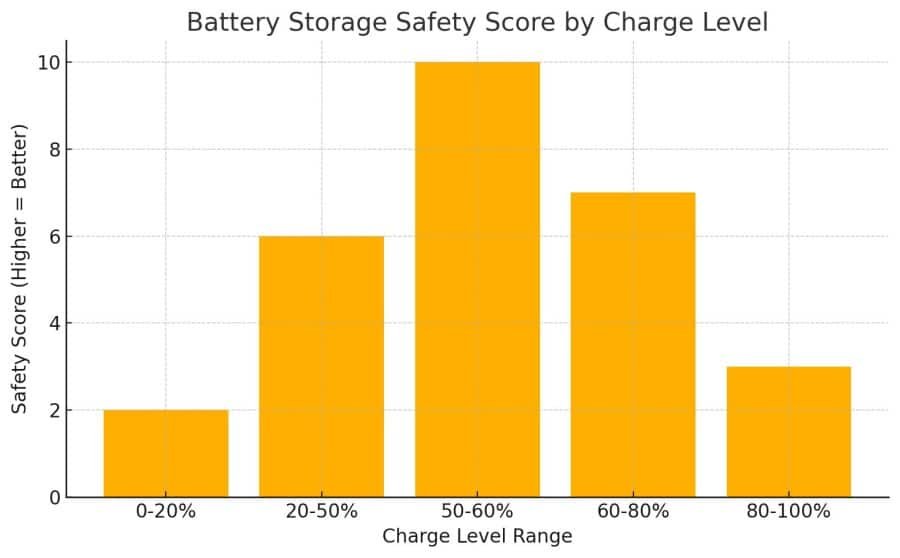

- Baterii skladujte při nabití přibližně 50–60% pokud se nebude používat déle než několik dní. Toto je považováno za optimální stav nabití pro zpomalení stárnutí buněk.

- Vyberte si chladné a suché vnitřní místo, V ideálním případě uchovávejte při teplotě 10–20 °C (50–68 °F), mimo dosah přímého slunečního záření a vlhkosti.

- Vyjměte baterii z kola pokud skladování překročí dva týdny, zejména pokud je kolo uloženo v neregulovaném prostoru.

Jak doporučil BikeRadar a dalšími orgány údržby by se s bateriemi elektrokol mělo zacházet podobně jako s vysoce výkonnou elektronikou, jako jsou notebooky. Neskladujte je v garážích, kůlnách nebo na půdách, kde se teploty mohou během dne výrazně měnit. Stabilní skladovací podmínky pomáhají zachovat bezpečnost i dlouhodobý výkon baterie.

3. Vizuální kontrola a čištění

Pravidelná vizuální kontrola baterie vašeho elektrokola je nezbytná pro odhalení včasných známek opotřebení nebo potenciálních bezpečnostních problémů. Lithium-iontové baterie jsou utěsněné a odolné, ale nejsou imunní vůči vnějšímu poškození nebo hromadění vlivů prostředí v průběhu času.

Co zkontrolovat:

- Hledejte jakékoli viditelné praskliny, otoky nebo deformace v pouzdře baterie. Vyboulené nebo nerovné povrchy mohou naznačovat hromadění plynu uvnitř nebo selhání článku a měly by být okamžitě řešeny.

- Zkontrolujte konektory a terminály kde se baterie připojuje k kolu. Hledejte známky koroze, rez nebo nahromaděné nečistoty, zejména pokud se kolo používá ve vlhkém nebo prašném prostředí.

Jak čistit:

- Použijte suchý hadřík z mikrovlákna jemně otřete vnější kryt. Nepoužívejte vodu ani agresivní čisticí prostředky.

- Pro elektrické kontakty naneste malé množství isopropylalkohol pomocí vatového tamponu nebo hadříku, který nepouští vlákna. Dbejte na to, abyste oblast nepřesákli.

Znečištěné nebo zkorodované konektory mohou vést k přerušovanému napájení, což má za následek neočekávané vypnutí motoru nebo spuštění chybových kódů systému. Čisté připojení pomáhají zajistit konzistentní elektrický výkon.

4. Prevence fyzického poškození

Přestože jsou baterie pro elektrokola vyrobeny s ochranným krytem, vnitřní komponenty zůstávají náchylné k nárazům nebo stlačení. Poškození, které není na povrchu okamžitě viditelné, může i tak ohrozit bezpečnost a spolehlivost baterie.

Proč na tom záleží:

Pád, rozdrcení nebo náraz do baterie může způsobit vnitřní zkraty mezi články, i když se vnější obal jeví neporušený. Tyto problémy mohou zůstat nepovšimnuty, dokud se neobjeví příznaky, jako je přehřátí, rychlé vybíjení nebo selhání nabíjení.

Ochranná opatření:

- Při přepravě odpojené baterie použijte polstrované pouzdro nebo pouzdro s tvrdou skořepinou k tlumení nárazů.

- V nákladních aplikacích, Nepokládejte těžké nebo ostré předměty přímo na baterii, zejména v brašnách nebo přihrádkách, kde je namontována baterie. Vibrace a tlak mohou postupně oslabovat strukturální integritu.

Bezpečnostní přezkum provedený společností SloHi Bike Co. zjistil, že 68% spontánních tepelných dějů v baterii (přehřátí nebo požáry), které vyšetřovali, se týkaly baterií s viditelným nebo dříve hlášeným poškozením pláště. Správná manipulace výrazně snižuje riziko takových poruch.

5. Likvidace a výměna

Všechny lithium-iontové baterie časem degradují. Po určitém počtu cyklů nabíjení a vybíjení se jejich kapacita plně nabít snižuje a pro udržení bezpečného a spolehlivého provozu kola je nutná jejich výměna.

Kdy vyměnit:

Většina baterií pro elektrokola je dimenzována pro 500–800 plných nabíjecích cyklů, po kterém kapacita často klesne pod původních 60–70%. To vede ke sníženému dojezdu, nekonzistentnímu výkonu a pomalejšímu nabíjení.

Co nedělat:

- Nikdy nevyhazujte baterie do koše, protože jsou považovány za nebezpečný odpad a mohou způsobovat požáry na skládkách.

- Nepropichujte, nedrťte ani nespalujte staré baterie, protože poškozené články mohou uvolňovat toxické plyny nebo se vznítit.

Správné metody likvidace:

- Použité baterie vraťte do Centra pro recyklaci elektronického odpadu nebo cyklistické obchody které se účastní recyklačních programů, jako je Call2Recycle.

- Mnoho obcí také přijímá baterie během akce svozu nebezpečného odpadu.

Bezpečná likvidace nejen chrání životní prostředí, ale také je v souladu s místními i mezinárodními předpisy týkajícími se likvidace baterií.

Běžné problémy a jejich řešení

1. Klesající dojezd baterie

Možné příčiny:

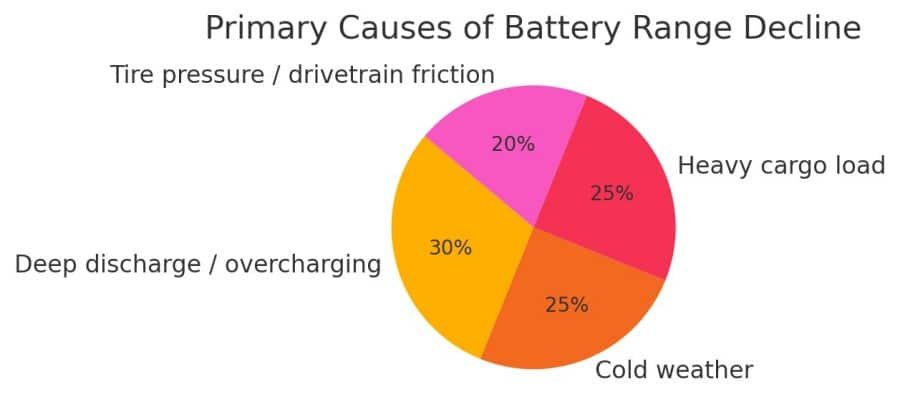

Postupné snižování dojezdu baterie je jedním z nejčastějších problémů, kterým čelí uživatelé nákladních elektrokol. K tomu může přispět několik faktorů:

- Časté cykly úplného vybití nebo přebití, které urychlují degradaci lithium-iontové baterie.

- Chladné počasí, které snižuje chemickou aktivitu uvnitř buněk a snižuje efektivní kapacitu.

- Těžké náklady, které zvyšují nároky na výkon motoru.

- Mechanický odpor, jako například podhuštěné pneumatiky nebo znečištěný hnací ústrojí, který nutí motor pracovat více.

Doporučená řešení:

- Udržovat správný tlak v pneumatikách dle doporučení výrobce pro snížení valivého odporu.

- Použití režimy Eco nebo s nižším příkonem na delších jízdách pro prodloužení dojezdu snížením výkonu motoru.

- Pokud je baterie více než tři roky starý nebo prošel několika stovkami nabíjecích cyklů, zvažte nahrazení, zejména pokud kapacita klesla pod 70%.

2. Zvýšený hluk motoru

Možné příčiny:

Neobvyklý nebo zvýšený hluk z motoru může naznačovat mechanické opotřebení nebo problémy s montáží. Mezi běžné zdroje patří:

- Opotřebovaná ložiska, zejména v jednotkách s nábojem nebo středním pohonem.

- Uvolněné montážní šrouby nebo momentové ramena, které mohou při zatížení vibrovat.

- Trosky nebo štěrk v převodovém systému, často postihující motory se středním pohonem s odkrytými vnitřními částmi.

Kroky k diagnostice a řešení:

- Ručně otočte klikovou hřídelí nebo zadním kolem zkontrolujte nepravidelné zvuky nebo odpor.

- Zkontrolujte vše úchyty motoru, momentové ramena a šrouby na těsnost pomocí vhodného nářadí.

- Pokud to váš model umožňuje, odstraňte vnější kryt motoru a zkontrolujte, zda v převodovém ústrojí nejsou nečistoty, opotřebení nebo špatné souosost.

FUCARE doporučuje pravidelná údržba motoru každých 2 000–3 000 kilometrů pro elektrokola používaná v každodenním komerčním nebo rozvozovém prostředí.

3. Samovybíjení během skladování

Proč k tomu dochází:

I když se nepoužívají, lithium-iontové baterie zažívají samovybíjení kvůli vnitřní chemické aktivitě. Navíc, Systém správy baterií (BMS) nepřetržitě odebírá malé množství energie pro sledování bezpečnostních parametrů, a to i při vypnutém kole.

Preventivní opatření:

- Dobijte baterii, aby Kapacita 50–60% každé 4 až 6 týdnů pokud je kolo uskladněno.

- Nikdy neskladujte baterii v plně vybitý stav, protože to může způsobit pokles napětí pod bezpečnou hranici, což může potenciálně spustit režim hlubokého spánku nebo trvalé vypnutí.

Dodržování těchto pokynů pro skladování pomáhá udržovat dlouhodobě v dobrém stavu baterie a zajišťuje spolehlivý provoz po opětovném uvedení kola do provozu.

Závěr

Správná údržba motorů a baterií je nejnákladově nejefektivnější způsob prodloužit životnost vašeho elektrického nákladního kola. Ať už kolo používáte na školní výlety, doručovací služby nebo na udržitelné dojíždění, rozdíl mezi plynulým provozem a frustrujícími poruchami často spočívá v běžná péče.

Jednoduchá měsíční rutina – kontrola šroubů, aktualizace softwaru, kontrola svorek a používání správných postupů nabíjení – může přidat roky k životnosti vašeho zařízení.

Nejde o technické znalosti. Jde o to být uvědomělý, proaktivní a důsledný.

Reference

- Velotric Bike. (2023). Kompletní kontrolní seznam údržby elektrokol.

https://www.velotricbike.com/blogs/story-landing/ultimate-ebike-maintenance-checklist - BikeRadar. (2023). Údržba elektrokola: jak se starat o své elektrokolo.

https://www.bikeradar.com/advice/workshop/electric-bike-maintenance - EBikeBC. (2022). Průvodce údržbou elektrokol.

https://ebikebc.com/pages/what-type-of-maintenance-does-an-e-bike-need - Reddit r/elektrická kola. (2023). Tipy pro správu stavu baterie elektrokola.

https://www.reddit.com/r/ebikes/comments/1776a5x/tips_for_managing_ebike_battery_health - Společnost SloHi Bike Co. (2022). Nejčastější dotazy k péči o baterie elektrokol.

https://www.slohibike.com/articles/e-bike-battery-care-faqs-pg210.htm - FUCARE BIKE EU. (2023). Pokyny pro péči o motorizované komponenty.

https://fucarebike.com - Blog o výzvě Marshmallow. (2022). Testy motoru elektrokol a vystavení vodě.

https://marshmallowchallenge.com

Prohlášení o autorských právech k obrázku

Některé obrázky použité na tomto webu/v tomto článku pocházejí z internetu a jsou určeny výhradně pro ilustrativní a vzdělávací účely, aby se lépe porozumělo obsahu. Respektujeme práva duševního vlastnictví původních tvůrců a snažíme se uvádět zdroje, kde je to relevantní.

Pokud jste právoplatným vlastníkem jakéhokoli zde zobrazeného obrázku a domníváte se, že jeho použití představuje porušení autorských práv, kontaktujte nás prosím na adrese info@regencargobikes.comPo ověření obrázek neprodleně odstraníme nebo uvedeme jeho zdroj.

Děkujeme za pochopení.

© Regen Technology Co., Ltd.