As bicicletas eléctricas (e-bikes), incluindo as e-bikes de carga, dependem de um sistema elétrico complexo para ligar a bateria, o motor, o controlador, os sensores e a interface do utilizador. Os protocolos de comunicação deste sistema funcionam como a "linguagem" que permite que todos estes componentes se coordenem sem problemas. Neste resumo de ciência popular, vamos explicar o que são estes protocolos de comunicação e como funcionam nos sistemas eléctricos das bicicletas eléctricas. Abordaremos os tipos de protocolos utilizados, as suas diferenças, onde cada um é aplicado, os seus prós e contras, considerações de custo, conformidade com as normas de segurança na UE e nos EUA e limitações. O objetivo é fornecer um guia claro e autorizado ao nosso cliente e público, equilibrando a profundidade técnica com a compreensão prática.

Componentes chave da E-Bike - O "Sistema Nervoso"

As bicicletas eléctricas podem ser consideradas como tendo um sistema nervoso central de fios e ligações de dados que ligam todos os componentes críticos. Tal como os nervos transportam sinais num corpo, a cablagem transporta sinais de energia e de dados através da bicicleta. Os principais componentes de um sistema elétrico típico de uma bicicleta eléctrica incluem

- Conjunto de baterias: A fonte de alimentação CC (normalmente 36-48 V) que fornece energia ao sistema. Liga-se ao controlador através de cabos de alimentação grossos (com fusíveis ou disjuntores para segurança) para fornecer a corrente principal. Algumas baterias avançadas também têm uma ligação de dados (através de linhas de comunicação) para partilhar sinais de estado ou de controlo com o controlador.

- Motor e controlador: O motor (motor de cubo numa roda ou uma transmissão intermédia na manivela) recebe energia do controlador do motor, que é o "cérebro" que regula a saída do motor com base nas entradas do ciclista e no feedback dos sensores. O controlador é uma unidade eletrónica com um microprocessador que recebe sinais (acelerador, sensor de pedal, travões, etc.) e gere a alimentação do motor. Normalmente, os motores têm fios de fase (cabos pesados que transportam energia) e fios de sensor (cabos finos de sensores de efeito Hall que fornecem feedback da posição do rotor) que vão para o controlador.

- Interface humana (acelerador, sensor de pedal, ecrã): O ciclista comunica com a bicicleta eléctrica através de dispositivos como o acelerador (frequentemente um punho do guiador com um sensor de efeito Hall que emite um sinal de tensão variável para solicitar a velocidade) e o sensor de assistência ao pedal (PAS) que detecta o movimento da pedalada através de ímanes e sensores. O visor no guiador mostra a velocidade, o nível da bateria, o nível de assistência, etc., e inclui frequentemente botões para o ciclista ajustar as definições. O ecrã e o controlador trocam dados através de um cabo multifilar que inclui linhas de alimentação e de comunicação.

- Interruptores de segurança (manetes de travão): As manetes de travão das bicicletas eléctricas têm normalmente interruptores de corte que enviam um sinal ao controlador para cortar imediatamente a potência do motor durante a travagem. Normalmente, é utilizado um circuito simples de dois fios para este efeito, actuando como um sinal de ligar/desligar para o controlador.

- Iluminação e acessórios: Muitas e-bikes também integram luzes dianteiras/traseiras, buzina, carregadores USB, etc. Estes podem ser controlados pelo controlador principal ou funcionar em circuitos separados, mas nos sistemas de topo de gama também podem ser tratados através do bus de comunicação.

Para um guia pormenorizado dos acessórios para bicicletas eléctricas e bicicletas de carga, pode leia este artigo para obter uma resposta mais completa ou talvez consultar o nosso Cargo Bike 101 página.

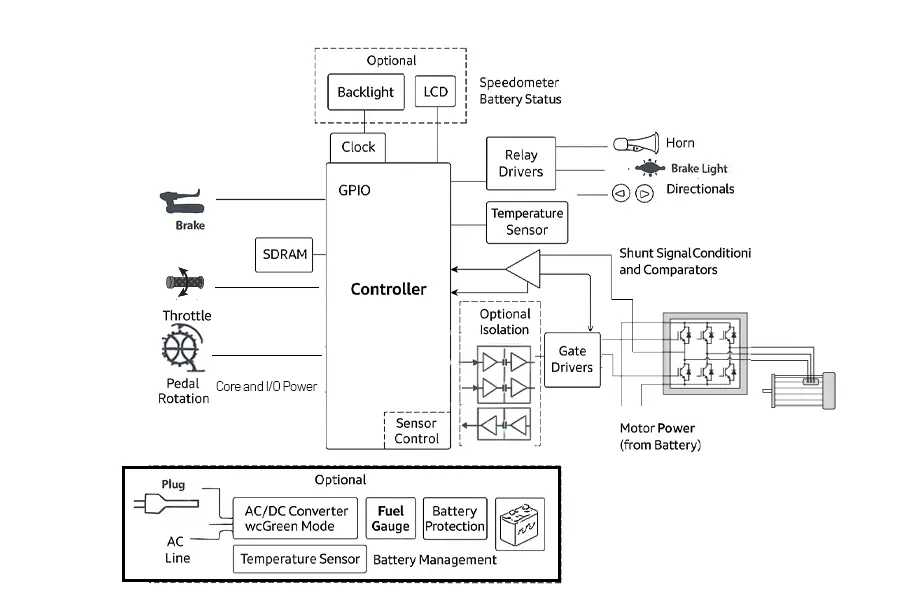

Figura 2: Diagrama de blocos de um sistema típico de controlo de bicicletas eléctricas e de gestão de baterias. O controlador central faz a interface com as entradas principais - acelerador, sensores de pedal, alavancas de travão - e gere as saídas, tais como sinais de acionamento do motor através de controladores de porta, controladores de relé e ligações GPIO. Módulos opcionais como ecrãs LCD, carregadores de bateria, indicadores de combustível e luzes de fundo aumentam a funcionalidade do sistema. A comunicação entre componentes permite a coordenação em tempo real da potência do motor, da iluminação, dos cortes de segurança e da monitorização do estado da bateria.

O que são protocolos de comunicação para bicicletas eléctricas?

No contexto das bicicletas eléctricas, os protocolos de comunicação referem-se ao método e formato pelo qual os componentes electrónicos trocam dados. As e-bikes antigas ou básicas não tinham uma rede digital complexa - muitos sinais eram analógicos ou simples circuitos de ligar/desligar. Por exemplo, um acelerador envia uma tensão analógica para indicar a potência pretendida pelo ciclista, e um interrutor de travão simplesmente abre ou fecha um circuito para cortar a potência. No entanto, à medida que as bicicletas eléctricas se tornaram mais sofisticadas - com ecrãs inteligentes, sensores avançados e até integração de GPS ou smartphone - surgiu a necessidade de uma comunicação digital mais robusta.

Atualmente, dois protocolos principais de comunicação digital dominam os sistemas de bicicletas eléctricas:

- UART (Universal Asynchronous Receiver-Transmitter): Um método de comunicação em série que cria uma ligação direta de dados um-para-um entre dois dispositivos (normalmente o controlador e o ecrã).

- Barramento CAN (Controller Area Network): Um protocolo de rede que permite que vários dispositivos (controlador, ecrã, BMS da bateria, sensores, etc.) comuniquem através dos mesmos fios de bus partilhados.

Para além do UART e do barramento CAN, dois outros protocolos de comunicação são ocasionalmente utilizados em sistemas de bicicletas eléctricas:

- SIF (Serial Interface Format): Trata-se de um protocolo proprietário ou simplificado que se encontra normalmente em certos sistemas de marca (por exemplo, Shimano STEPS ou unidades de ecrã mais antigas). É normalmente utilizado para a troca de dados básicos entre o controlador e o ecrã ou botões remotos. Uma vez que o SIF carece de uma normalização aberta e de flexibilidade, está sobretudo limitado a marcas específicas ou a modelos antigos.

- RS-485 (Norma recomendada 485): O RS-485 é um protocolo de comunicação em série de nível industrial conhecido pela sua fiabilidade a longa distância e resistência ao ruído. Embora não seja tão comum como o UART ou o CAN nas bicicletas eléctricas de consumo, aparece em alguns sistemas de frotas comerciais ou de topo de gamaespecialmente quando é necessária robustez e cablagem prolongada - como bicicletas partilhadas, frotas de aluguer ou bicicletas eléctricas para trabalhos pesados.

Estes protocolos são essencialmente as "línguas" da eletrónica da bicicleta eléctrica. Se todos os componentes falarem a mesma língua, a informação flui corretamente; caso contrário, os dispositivos não se entenderão. É por isso que a correspondência do protocolo é fundamental quando se emparelha um ecrã com um controlador, por exemplo. Mesmo que a ficha encaixe, uma incompatibilidade no protocolo significa que as peças não funcionarão em conjunto.

Visão geral da utilização do mercado (tendências estimadas para 2024-2025)

Embora não exista uma repartição universalmente publicada da utilização de protocolos no mercado das bicicletas eléctricas, com base nos conhecimentos da indústria e nos principais fornecedores de sistemas (por exemplo, Bosch, Bafang, Shimano, Mahle, etc.), o seguinte é um distribuição estimada razoável a partir de 2025:

| Protocolo | Quota de utilização (estimada) | Aplicações comuns | Notas |

|---|---|---|---|

| UART | ~50-60% | Bicicletas eléctricas de nível básico e médio | Amplamente utilizado devido à sua simplicidade e baixo custo |

| Barramento CAN | ~30-35% | Bicicletas eléctricas topo de gama, inteligentes ou modulares | Aumentar a adoção com integração inteligente |

| RS-485 | ~5-10% | Sistemas de frotas, instalações comerciais com fios longos | Limitado a casos de utilização específicos |

| SIF / Proprietário | <5% | Sistemas específicos da marca ou antigos | Encontrado principalmente em ecossistemas mais antigos ou fechados |

Nota: Estes valores são generalizados aos mercados globais (UE, CN, NA) e baseiam-se nas tendências dos OEM, documentação pública, dados de desmontagem e informações dos fornecedores de componentes.

Definir protocolos de comunicação de E-Bike de forma mais fácil :

Em termos simples, os protocolos de comunicação nas bicicletas eléctricas são os seguintes linguagens ou regras que permitem que diferentes componentes electrónicos falem entre si. Se os componentes não falarem a mesma língua, não se conseguem entender - mesmo que a ficha encaixe fisicamente.

📞 Analogia: Chamada individual vs. Chat em grupo

Vamos imaginar duas formas de comunicação na vida quotidiana para compreender os protocolos das bicicletas eléctricas:

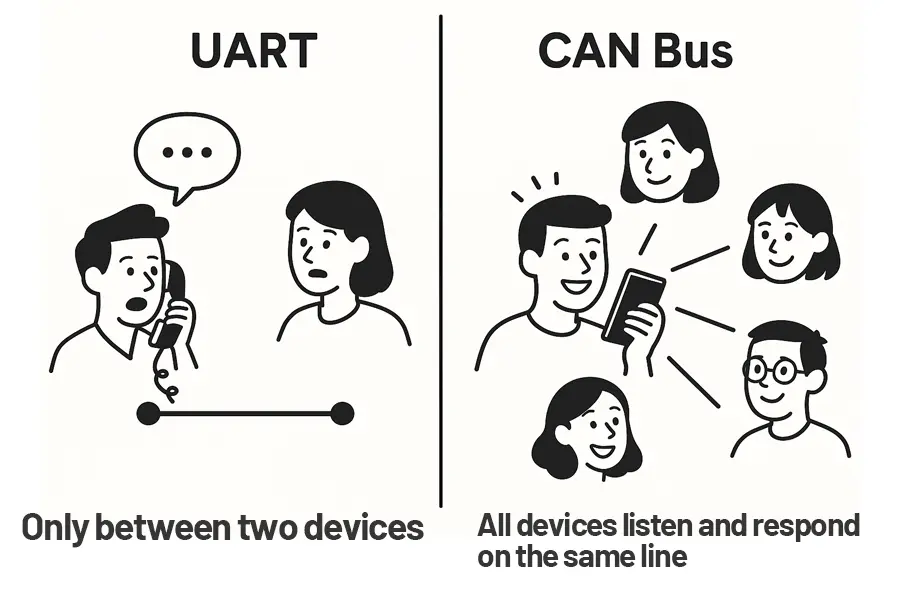

UART: Como uma chamada telefónica individual

- A UART (Universal Asynchronous Receiver-Transmitter) é como ligar a um amigo pelo telefone.

- Apenas dois dispositivos podem falar ao mesmo tempo - como o ecrã e o controlador.

- Para falar com outro dispositivo, é necessário outro fio (ou outra chamada telefónica).

- É simples, mas não é escalável quando se tem muitos dispositivos.

- Comum em sistemas básicos para bicicletas eléctricas com caraterísticas limitadas.

AN Bus: Como um chat de grupo

- O barramento CAN (Controller Area Network) é como um conversação em grupo no WhatsApp ou no WeChat.

- Todos os dispositivos (controlador, bateria, ecrã, sensor, luzes) estão na mesma sala de conversação.

- Cada mensagem é identificada com um ID de remetente e cada dispositivo lê apenas as mensagens que lhe são destinadas.

- É muito mais eficiente e ideal quando há muitos componentes que precisam de trabalhar em conjunto.

- Utilizado em sistemas inteligentes e avançados para bicicletas eléctricasfrequentemente com GPS, Bluetooth e integração de aplicações.

| Recurso | UART (Chamada telefónica) | CAN Bus (Conversa de grupo) |

|---|---|---|

| Tipo de ligação | Um para um (ponto a ponto) | Um para muitos (barramento partilhado) |

| Escalabilidade | Baixo - necessita de fios adicionais para mais dispositivos | Elevada - vários dispositivos partilham os mesmos fios |

| Fluxo de comunicação | Apenas entre dois dispositivos | Todos os dispositivos ouvem e respondem na mesma linha |

| Complexidade | Simples | Mais complexo mas poderoso |

| Caso de uso | Bicicletas eléctricas básicas (apenas ecrã ↔ controlador) | Bicicletas eléctricas inteligentes com BMS, aplicação, sensores, etc. |

O papel dos protocolos de comunicação

Os protocolos de comunicação nas bicicletas eléctricas têm vários objectivos importantes:

- Partilha de dados: Permitem que o controlador envie dados em tempo real para o ecrã (velocidade, estado de carga da bateria, códigos de erro) e receba comandos de volta (por exemplo, alterar o nível de assistência, ligar/desligar as luzes). Sem um protocolo adequado, pode não obter uma leitura fiável da velocidade ou pode não conseguir ajustar as definições.

- Coordenação de componentes: Em sistemas avançados, é necessário coordenar vários microcontroladores. Por exemplo, uma bateria inteligente com o seu próprio sistema de gestão de baterias (BMS) pode comunicar com o controlador do motor para evitar sobrecargas de corrente ou para apresentar a percentagem exacta da bateria. Um bus CAN ou uma rede semelhante permite que a bateria, o controlador do motor, o ecrã e até os sensores partilhem informações numa rede com vários nós.

- Segurança e fiabilidade: Um protocolo bem concebido garante que, se houver uma falha ou uma perda de sinal (por exemplo, um cabo danificado), o sistema pode detectá-la e tomar medidas seguras (como cortar a potência do motor). Protocolos robustos como o CAN incluem verificação de erros e priorização de mensagens para lidar com isso. Os sinais analógicos mais simples não têm esse tipo de tratamento de erros - se um fio do acelerador se soltar, o controlador pode interpretar erradamente o ruído como um sinal de aceleração, a menos que existam disposições de segurança.

- Expansibilidade: Para e-bikes com muitas funcionalidades (localizadores GPS, imobilizadores antirroubo, sensores de assistência múltipla, etc.), uma rede de comunicação facilita a adição ou remoção de dispositivos. Em vez de cada novo dispositivo necessitar de uma ligação eléctrica dedicada ao controlador, um dispositivo pode juntar-se ao barramento comum e partilhar dados com todos os outros. Esta escalabilidade é uma das principais razões pelas quais as bicicletas eléctricas modernas de topo de gama estão a avançar para o barramento CAN.

Em resumo, o protocolo de comunicação é a espinha dorsal do sistema elétrico da bicicleta eléctrica, garantindo que todas as peças electrónicas funcionam em conjunto. Noutro artigo, vamos analisar os dois principais tipos de protocolo (UART e CAN), examinando como cada um funciona e os seus respectivos casos de utilização em e-bikes e bicicletas eléctricas de carga. verifique se está interessado:

- "Compreender a UART nas bicicletas eléctricas: Como a comunicação serial simples potencializa seu passeio"

- Um guia para principiantes sobre como a UART permite a troca de dados básicos entre componentes de bicicletas eléctricas, como ecrãs e controladores.

- "O que é o barramento CAN nas bicicletas eléctricas? Uma forma mais inteligente de ligar baterias, sensores e muito mais"

- Saiba como as bicicletas eléctricas modernas utilizam o barramento CAN para suportar a comunicação entre vários dispositivos, ecrãs avançados e diagnósticos do sistema.

Cenários de aplicação: Que protocolo de comunicação para que bicicleta eléctrica?

É útil compreender como a UART e a CAN são escolhidas na prática para diferentes projectos de bicicletas eléctricas. Vamos considerar duas grandes categorias: bicicletas eléctricas para uso doméstico (incluindo as bicicletas de uso diário ou de lazer) e e-bikes de carga/frota (frequentemente utilizadas para entregas comerciais ou por frotas de aluguer), tendo em conta que estas têm frequentemente prioridades diferentes.

- Bicicletas eléctricas de consumo padrão (bicicletas eléctricas de cidade, montanha e estrada): Estas são as bicicletas que muitos indivíduos compram para uso pessoal. Vão desde o nível de entrada até ao topo de gama. No segmento inferior (modelos sensíveis ao custo), a comunicação UART é extremamente comum. Por exemplo, uma simples bicicleta eléctrica de 36V com um sensor de cadência e um ecrã LED básico utiliza provavelmente uma UART (ou mesmo sinais analógicos) entre o controlador e o ecrã mínimo que possui. O foco aqui é relação custo-eficácia e funcionalidade básica. Muitas dessas bicicletas utilizam controladores e ecrãs amplamente disponíveis que aderem a um protocolo UART de facto, o que significa que as marcas de bicicletas podem adquirir componentes de diferentes OEM. Isto é atrativo para os compradores B2B que querem ter a flexibilidade de utilizar, por exemplo, um ecrã mais bonito do fornecedor A com um controlador do fornecedor B - desde que ambos falem UART no mesmo formato, pode funcionar (embora seja necessário verificar a compatibilidade em termos de pinagens e firmware). Nas bicicletas de consumo topo de gama, especialmente as fabricadas por grandes marcas, há uma tendência para o barramento CAN. As e-MTBs ou e-road bikes de alto desempenho com sensores de binário e ecrãs sofisticados podem utilizar o CAN para integrar tudo sem problemas. No entanto, algumas marcas continuam a utilizar UART ou outras ligações em série proprietárias, mesmo em bicicletas topo de gama; varia consoante o fabricante e a sua filosofia de design.

- Bicicletas eléctricas de carga e frotas comerciais: As e-bikes de carga são concebidas para transportar cargas pesadas ou passageiros e são frequentemente utilizadas por empresas (serviços de entrega, bicicletas postais, etc.). Estas bicicletas tendem a dar prioridade robustez, segurança e capacidades de gestão de frotas sobre o custo da eletrónica. É neste segmento que o barramento CAN ganhou realmente terreno. Por exemplo, as bicicletas de carga podem ter baterias duplas para aumentar a autonomia - a gestão de duas baterias requer comunicação para equilibrar a descarga ou, pelo menos, para comunicar o estado de cada uma. O CAN facilita a comunicação de um controlador com duas unidades BMS (uma em cada bateria) no mesmo bus. As bicicletas de carga também podem ter acessórios adicionais: luzes de travão, piscas, até fechaduras electrónicas - coordená-los através de um bus central simplifica a cablagem e o controlo. Além disso, como as bicicletas eléctricas de carga funcionam frequentemente em frotas, as empresas gostam de ter telemática nelas: Localizadores GPS que podem comunicar a localização da bicicleta, a sua utilização e eventuais falhas. Com um sistema compatível com CAN, um módulo de telemática pode simplesmente escutar as mensagens CAN sobre velocidade, estado da bateria, etc., e carregar essa informação. De facto, um estudo de caso com uma frota de entregas europeia demonstrou que a ligação ao barramento CAN permitia a monitorização remota de dados de manutenção (como a quilometragem), a desativação remota do motor para antirroubo e actualizações over-the-air do firmware da bicicleta - caraterísticas extremamente úteis para a gestão da frota. Isto seria complicado de implementar numa bicicleta baseada em UART.

- Sistemas mistos e combinados vs. sistemas integrados: Se uma marca de bicicletas eléctricas quiser ter a liberdade de misturar componentes ou permitir actualizações pós-venda, tende a manter os sistemas baseados em UART. Vimos que Os sistemas UART permitem a troca de ecrãs ou o ajuste rápido das definições do motor. Uma empresa de bicicletas eléctricas mais pequena pode preferir esta via para evitar ficar presa a um único fornecedor - pode mudar de fornecedor de motor/controlador sem alterar todo o ecossistema, desde que o protocolo continue a ser UART e possa adaptar o firmware. Por outro lado, As marcas centradas na otimização e conformidade do sistema escolhem frequentemente a CAN. Por exemplo, as bicicletas eléctricas da Bosch utilizam um bus do tipo CAN (a Bosch tem um protocolo proprietário baseado no CAN) que liga o motor, o ecrã e a bateria. Isto assegura que nenhuma peça de terceiros possa interferir; tudo está finamente sintonizado em conjunto. A vantagem é a excelente fiabilidade e segurança - o sistema emite um erro se algo estiver fora das especificações. A desvantagem é que, como comprador B2B (como um OEM de bicicleta que escolhe a Bosch), está a comprometer-se a comprar o motor, o controlador, a bateria e o ecrã todos da Bosch como um pacote.

- Bicicletas de carga - Considerações específicas: As bicicletas de carga, especialmente na UE, são frequentemente sujeitas a um controlo mais rigoroso, uma vez que podem transportar cargas mais pesadas ou mesmo passageiros. Na Alemanha, por exemplo, existe uma norma (DIN 79010) específica para a segurança das bicicletas de carga (sobretudo aspectos mecânicos, como a resistência do quadro e a travagem). Embora essa norma não dite os protocolos de comunicação, a mentalidade de segurança em primeiro lugar em bicicletas de carga incentiva a utilização de um protocolo que pode garantir, por exemplo, que se algo correr mal (sobreaquecimento do motor ou bateria fraca), o sistema pode comunicá-lo e tomar medidas. A robustez e o tratamento de erros do CAN ajudam a atingir estes objectivos de segurança. Além disso, as bicicletas eléctricas de carga funcionam frequentemente em ambientes urbanos (entregas nas cidades) onde existe muito ruído de rádio/elétrico e os riscos são elevados se ocorrer um erro de comunicação no momento errado. O imunidade ao ruído do CAN é uma grande vantagem, pois evita falhas de comunicação que podem levar a comportamentos erráticos.

Apenas 20 bicicletas por encomenda para começar

Bicicleta E-Cargo personalizável - RS01

Quer seja uma marca em crescimento ou uma loja de bairro, as nossas bicicletas de carga resistentes são o seu bilhete para o mundo em expansão das entregas ecológicas. Vamos lá!

Normas de segurança e conformidade do sistema elétrico (UE/EUA)

Independentemente do protocolo de comunicação utilizado, os sistemas eléctricos das bicicletas eléctricas têm de cumprir as normas de segurança para garantir que funcionam de forma segura e legal, especialmente em mercados-chave como a Europa e os Estados Unidos. O protocolo de comunicação pode afetar indiretamente a conformidade de uma bicicleta - por exemplo, um protocolo que permita modificações sem restrições por parte do utilizador pode representar um risco de conformidade, ao passo que um protocolo bloqueado pode ajudar a garantir que a bicicleta se mantém dentro dos limites legais. Vamos analisar as normas relevantes e a forma como se relacionam:

Como é que os protocolos de comunicação afectam a conformidade das bicicletas eléctricas na União Europeia

União Europeia (UE) - EN 15194: Na UE, a maioria das bicicletas eléctricas (bicicletas de assistência a pedal com potência do motor <= 250W e corte de assistência a 25 km/h) são classificadas como EPACs (Ciclos assistidos eletronicamente). A norma EN 15194 aplica-se às EPAC e define requisitos e métodos de ensaio para a segurança e o desempenho. Isto inclui a segurança mecânica (travões, quadro, etc.) e a segurança eléctrica (cablagem, CEM, etc.), bem como a garantia de que a bicicleta cumpre os limites de velocidade e potência.

- Para os protocolos de comunicação, um aspeto relevante é compatibilidade electromagnética (CEM)O sistema não deve emitir interferências excessivas nem ser indevidamente afetado por interferências. Uma linha de comunicação CAN ou UART bem concebida deve passar nos testes de CEM (a norma EN 15194 remete para a norma EN 55014 ou similar para a CEM). O carácter resistente ao ruído do CAN pode ser uma vantagem para cumprir estes requisitos de compatibilidade electromagnética, uma vez que lida melhor com o ruído, mas os sistemas UART também podem estar em conformidade se forem devidamente blindados.

- Violação de velocidade e potência: A norma EN 15194 exige que a assistência seja interrompida a 25 km/h e que o utilizador não possa ajustar facilmente este limite acima do valor legal. Se uma bicicleta utilizar UART e o fabricante deixar os blocos de programação acessíveis, um utilizador poderia potencialmente desrestringi-lo - o que pode levantar problemas de conformidade. Por isso, alguns fabricantes utilizam sistemas CAN bloqueados especificamente para evitar que os utilizadores alterem o limite de velocidade. Por exemplo, os motores baseados em CAN da Bafang têm o limite de velocidade fixo e não alterável através do ecrã, o que ajuda a garantir a conformidade com os regulamentos logo à partida. Em contraste, em muitos sistemas UART, um utilizador experiente pode entrar no modo de definições no visor e ajustar o tamanho ou o limite da roda, ou utilizar um cabo de programação, o que pode infringir a lei se fizer a bicicleta ultrapassar os 25 km/h de assistência.

- Segurança eléctrica: A norma EN 15194 (últimas revisões) abrange a segurança eléctrica básica mas, curiosamente não cobre totalmente a segurança da bateria - parte do princípio de que o próprio conjunto de baterias deve cumprir outras normas. Centra-se mais na integração, na cablagem e na proteção básica (como a ausência de peças sob tensão expostas, etc.). Um protocolo de comunicação não tem impacto direto nisto, mas indiretamente, um protocolo como o CAN que permita ao BMS falar com o controlador pode aumentar a segurança - por exemplo, o BMS pode enviar um comando "parar descarga" se a bateria estiver a sobreaquecer. Embora não seja obrigatório pela norma EN 15194, este tipo de funcionalidade ajuda a bicicleta a cumprir as expectativas gerais de segurança (evitando eventos de fuga térmica).

Além disso, as bicicletas eléctricas de carga europeias (especialmente as que transportam mercadorias/passageiros) poderão ter de cumprir a Diretiva Máquinas se não se enquadrarem estritamente nas regras aplicáveis às bicicletas (alguns ciclos de carga pesados enquadram-se). Mais uma vez, isto realça a necessidade de dispositivos de segurança robustos. A utilização de um protocolo de comunicação sólido com um comportamento à prova de falhas (como o facto de o CAN se desligar em caso de falha) pode contribuir para a conformidade neste caso.

Mais informações sobre Norma da UE para bicicletas eléctricas

Como é que os protocolos de comunicação afectam a conformidade das bicicletas eléctricas nos Estados Unidos

Estados Unidos - UL 2849 e outros: Nos EUA, o fabrico de bicicletas eléctricas está um pouco menos regulamentado a nível federal no que diz respeito ao desempenho (existe uma definição de produto de consumo de uma bicicleta eléctrica de baixa velocidade como 750 W no máximo e 20 mph no acelerador/28 mph no pedal assistido, mas não existem normas de construção obrigatórias a nível federal). No entanto, a certificação de segurança está a tornar-se crucialespecialmente devido a preocupações com incêndios provocados pelas baterias.

- UL 2849 é a principal norma de segurança para sistemas eléctricos de e-bikes na América do Norte. Abrange todo o sistema de acionamento elétrico de uma e-bike - incluindo a bateria, o motor, o carregador e todas as interligações. Os testes UL 2849 analisam aspectos como a capacidade da cablagem para suportar as correntes, se o sistema está protegido contra curto-circuitos e, mais importante, também incorpora UL 2271 para baterias (que é uma norma de segurança específica para baterias). Em termos de comunicação, a UL 2849 não prescreve um protocolo, mas verifica se, por exemplo, se a comunicação se perder ou se for detectada uma falha, o sistema falha em segurança (sem eventos térmicos, sem motor em fuga). Um sistema baseado em CAN pode ter uma ligeira vantagem na prova de redundância (por exemplo, se a mensagem do acelerador se perder, o CAN pode detectá-lo e fazer um time-out adequado). Mas mesmo os sistemas UART podem ser concebidos para cumprir a norma UL 2849 (apenas necessitam de um tratamento completo das falhas no firmware do controlador).

- Prevenção de incêndios e choques eléctricos: Normas como a UL 2849 centram-se na prevenção de incêndios e choques eléctricos. Por exemplo, se uma bicicleta eléctrica tiver um carregador ligado, a comunicação entre a bateria e o carregador (se existir) não deve conduzir a uma sobrecarga. Nomeadamente, a norma Norma EnergyBus que mencionámos, que se baseia no CAN, foi parcialmente motivado pela segurança - garantindo que qualquer carregador pode carregar qualquer bateria em segurança, comunicando através do CANopen e só permitindo a alimentação quando é efectuado um aperto de mão adequado. O EnergyBus utiliza um conetor específico que inclui linhas de dados CAN, de modo a que o carregador e a bateria estabeleçam primeiro a comunicação e, em seguida, permitam a corrente de carga, para evitar faíscas ou tensões incompatíveis. Este conceito alinha-se bem com a lógica de segurança UL. Se uma marca estiver a utilizar o EnergyBus, é provável que ajude a passar nas certificações de segurança, porque gere inerentemente interações seguras entre componentes.

- Conformidade regulamentar (velocidade/potência): Nos EUA, o sistema de classes (e-bikes de Classe 1, 2, 3) é em grande parte um sistema de honra e não é tão rigorosamente aplicado como os limites da UE, mas por razões de responsabilidade, os fabricantes normalmente asseguram que uma e-bike vendida como Classe 2 não pode ser facilmente alterada para exceder 20 mph no acelerador, por exemplo. Também neste caso, a utilização de um protocolo CAN fechado pode ajudar - os utilizadores não podem simplesmente ligar um cabo e desativar a bicicleta. É de salientar que muitas empresas de bicicletas eléctricas anunciam agora baterias ou sistemas com certificação UL para garantir a segurança dos clientes. Por exemplo, a HOVSCO (como se pode ver na sua base de conhecimentos) salienta que as suas bicicletas cumprem a norma UL 2849 para a segurança eléctrica e a norma EN 15194 para a conformidade geral de segurança. Isto significa que a cablagem, os conectores e as comunicações devem funcionar sem causar riscos.

Normas internacionais e outras normas: Para além da EN 15194 e da UL 2849, existem outras normas relevantes - por exemplo, ISO 4210 (norma de segurança para bicicletas) com uma parte que abrange os requisitos das bicicletas eléctricas, e a norma alemã DIN 79010 para bicicletas de carga (que, como referimos, abrange aspectos como a resistência do quadro a cargas e o desempenho da travagem). Estes não ditam diretamente a eletrónica, mas uma norma para bicicletas de carga pode implicitamente exigir que, por exemplo, a assistência não funcione mal sob carga pesada. Uma comunicação robusta garante que, mesmo que a bicicleta esteja em esforço (e talvez o ruído elétrico esteja a aumentar ou a bateria esteja a ficar fraca), os sinais entre a bateria, o controlador e os sensores permanecem fiáveis.

Resumindo, a conformidade e a segurança conduzem a algumas decisões de conceção entre UART e CAN. Um fabricante que pretenda a máxima segurança pode inclinar-se para o CAN pela sua verificação e controlo de erros, ou implementar salvaguardas adicionais nos sistemas UART. Ambos os protocolos podem fazer parte de um projeto seguro, mas a forma como são utilizados é fundamental. O protocolo a natureza fechada dos sistemas CAN pode impor a conformidade (por exemplo, limites de velocidade não ajustáveis pelos utilizadores, tal como exigido por lei) , enquanto Os sistemas UART oferecem mais liberdade ao utilizador, o que é uma faca de dois gumes. Os fabricantes têm de garantir que mesmo as bicicletas baseadas em UART têm coisas como um limitador físico ou de software que não pode ser facilmente pirateado, para se manterem dentro dos limites legais.

Por último, independentemente do protocolo, a utilização de conectores e cablagem de qualidade faz parte da conformidade. Na UE, a bicicleta tem de suportar vibrações sem que os fios se soltem e em condições de humidade sem entrar em curto-circuito. Conectores como o Higo/Julet (conectores à prova de água amplamente utilizados em bicicletas eléctricas) são populares não só pela sua conveniência, mas também porque ajudam a cumprir Classificações IP e requisitos de fiabilidade. Um bus CAN utiliza normalmente estes conectores (por exemplo, um único Higo de 4 ou 5 pinos pode transportar os dados CAN e a alimentação de um ecrã). A escolha do protocolo não altera a necessidade de um bom alívio de tensão, isolamento e conectores de bloqueio para evitar desconexões (que podem ser perigosas se, por exemplo, o sinal de corte do travão não chegar ao controlador porque um cabo se soltou).

Para concluir esta secção, tanto a Europa como os EUA estão agora muito atentos à segurança das bicicletas eléctricas. A conformidade com normas como a EN 15194 e a UL 2849 é cada vez mais inegociável para as marcas de renome. O protocolo de comunicação é uma peça do puzzle - um meio de garantir que o sistema elétrico é coordenado e à prova de falhas. A fiabilidade do barramento CAN pode ajudar a cumprir estas normas, proporcionando uma comunicação robusta, enquanto os sistemas UART requerem uma conceção cuidadosa para serem igualmente seguros. Os fabricantes escolherão frequentemente o protocolo que melhor se alinha com a estratégia de conformidade: UART para projectos mais simples, em que o risco pode ser gerido facilmente, ou CAN para sistemas complexos, em que as suas caraterísticas de segurança se destacam.

Custos e considerações de mercado ao escolher os protocolos de comunicação

Ao decidir entre protocolos de comunicação (ou, de um modo geral, ao conceber o sistema elétrico de uma bicicleta eléctrica), o custo é um fator importante - não apenas o custo monetário, mas também o "custo" em termos de flexibilidade e de relações com os fornecedores. Eis como os custos se comparam e o que os compradores ou engenheiros B2B consideram:

- Custo do hardware: Como referido anteriormente, um sistema baseado em UART utiliza normalmente hardware mais simples. O controlador e o ecrã apenas necessitam de capacidade UART, que praticamente todos os microcontroladores têm incorporada. A cablagem pode ser um pouco mais simples (menos considerações de terminação, etc.). Um sistema baseado em CAN exige um pouco mais: um chip transcetor CAN para cada dispositivo e, possivelmente, um MCU mais potente (embora, atualmente, até os MCU bastante baratos tenham CAN incorporado). A diferença real de BOM (Bill of Materials) pode ser da ordem de apenas alguns dólares por bicicleta em grandes volumes, mas num mercado competitivo, isso não deixa de ser importante. Para uma encomenda de um grande parque de bicicletas, esses dólares multiplicam-se. Dito isto, o o custo do hardware CAN diminuiu significativamente, e o compromisso pode ser facilmente justificado pela funcionalidade adicional que o CAN proporciona.

- Custo de desenvolvimento e integração: Para uma startup de bicicletas eléctricas ou uma pequena empresa, desenvolver um sistema baseado em CAN a partir do zero pode ser dispendioso se não tiverem conhecimentos internos. Pode envolver a contratação de engenheiros de sistemas incorporados familiarizados com o CAN, investir em ferramentas e gastar tempo a desenvolver firmware personalizado. Em alternativa, se comprarem um sistema pronto a usar (como as unidades de transmissão Bosch ou Shimano, que são baseadas em CAN), o custo de desenvolvimento é mais baixo, mas o custo unitário é mais elevado (os sistemas Bosch têm um preço mais elevado, em parte porque se obtém uma solução totalmente integrada e o nome da marca). A O sistema UART pode frequentemente ser montado com componentes prontos a utilizar com compatibilidade conhecida - por exemplo, muitas empresas utilizam protocolos standard ou de código aberto, em que grande parte da engenharia já está feita e o risco é menor. Para um comprador B2B (por exemplo, uma empresa que pretende ter um conjunto de bicicletas eléctricas com a sua marca), optar por UART pode significar que pode adquirir peças genéricas mais baratas, enquanto optar por CAN significa frequentemente alinhar-se com o ecossistema de um determinado fornecedor (que pode cobrar licenças ou preços mais elevados).

- Custos de manutenção e pós-venda: Este aspeto é por vezes ignorado. Um operador de frota (como uma empresa de partilha de bicicletas ou uma empresa de entregas) pode constatar que Bicicletas de autocarro CAN poupam dinheiro na manutenção. Porquê? Porque podem diagnosticar os problemas à distância ou mais rapidamente. Um sistema ligado ao CAN pode comunicar códigos de erro em pormenor (por exemplo, "falha no sensor de temperatura da bateria #2" como um código específico). Os técnicos podem ligar ferramentas de diagnóstico ao bus CAN para identificar os problemas. Isto pode reduzir o tempo de trabalho. Além disso, como se viu no caso da IoT Venture, é possível fazer actualizações remotas de firmware, o que pode poupar o custo de recolher fisicamente as bicicletas para determinadas reparações. Por outro lado, a manutenção inicial de uma bicicleta UART pode ser mais simples (talvez haja menos coisas que possam correr mal nas comunicações), mas se algo estiver errado, poderá ser necessário fazer trocas de peças por tentativa e erro, uma vez que o sistema não pode dizer exatamente o que está errado, para além de um LED a piscar. Para um consumidor individual, uma bicicleta com UART pode ser mais barata de reparar porque pode usar peças prontas a usar e o conhecimento da comunidade para a reparar, enquanto uma bicicleta com CAN pode obrigá-lo a ir a um serviço autorizado (potencialmente mais caro). Assim, há um compromisso de custo entre facilidade de manutenção pelo utilizador (vitórias UART) e apoio avançado ao diagnóstico (a CAN ganha, o que poderá reduzir os custos dos serviços profissionais).

- Custos de licenciamento e de propriedade: A utilização de um protocolo CAN proprietário pode implicar taxas de licenciamento ou restrições. Se uma marca de bicicletas desenvolver o seu próprio protocolo CAN, tudo bem, mas se utilizarem algo como o CANopen ou o EnergyBus, poderão ter de aderir a normas e, possivelmente, juntar-se a associações (por exemplo, EnergyBus e.V.). Estes custos são geralmente reduzidos, mas vale a pena registar. Sistemas proprietários como os da Bosch significam efetivamente que o OEM da bicicleta compra as unidades de transmissão como um pacote; a Bosch estabelece o preço. Com os sistemas UART, existe frequentemente mais concorrência entre os fornecedores de peças, o que pode fazer baixar os preços.

- Perceção do cliente e valor: Do ponto de vista do marketing, uma marca pode justificar um preço mais elevado para uma bicicleta que tenha "eletrónica de barramento CAN de nível automóvel", uma vez que parece avançada e fiável (mesmo que o cliente não veja diretamente a diferença). Há valor na toque e desempenho de primeira qualidade que os sistemas CAN frequentemente acompanham (estão normalmente presentes em bicicletas que também têm motores de alta qualidade, etc.). Assim, as marcas que visam o mercado de topo de gama ou os clientes comerciais podem tirar partido do CAN como parte de uma oferta premium. Por outro lado, para as bicicletas eléctricas de entrada de gama, os clientes preocupam-se sobretudo com o funcionamento e o preço acessível - não vão pagar mais só porque o visor da bicicleta utiliza CAN em vez de UART. Portanto, a escolha do protocolo deve estar de acordo com o segmento de mercado da bicicleta.

- Preparar o futuro: Um custo que os engenheiros consideram é o custo de oportunidade de não estar preparado para o futuro. Se investir numa plataforma baseada em UART agora, mas no próximo ano quiser adicionar mais funcionalidades (por exemplo, uma segunda bateria ou um novo tipo de sensor), pode achar que a plataforma antiga é limitadora, obrigando a uma nova conceção. Algumas empresas decidem que, a longo prazo, é mais económico optar pelo CAN desde o início, mesmo que não seja totalmente utilizado, para deixar espaço para novas funcionalidades e acessórios. Isso pode economizar custos de redesenvolvimento no futuro. É uma decisão estratégica: pagar um pouco mais adiantado vs. potencialmente muito mais tarde para atualizar.

Em termos de preços reais: é difícil de determinar, mas um especialista do sector poderia dizer, por exemplo, que um conjunto básico de controlador UART para bicicletas eléctricas + ecrã pode custar, digamos, $50-$100 a granel, enquanto um conjunto equivalente baseado em CAN de uma grande marca pode custar algumas centenas de dólares (porque é mais sofisticado). No entanto, essa diferença muitas vezes inclui também um melhor desempenho do motor, garantia, etc., e não apenas a diferença de comunicação. O custo adicional exclusivamente para o protocolo (por exemplo, adicionar um chip CAN) é pequena, mas a custo do ecossistema (ligação a um sistema caro versus um sistema genérico barato) pode ser grande.

Em termos simples, para um comprador de bicicletas eléctricas B2B:

- Se a sua prioridade é custo unitário mais baixo e pretende flexibilidade para se abastecer junto de vários fornecedores, um Sistema aberto baseado em UART é atrativo. Pode comprar ecrãs e controladores que combinem entre si e até negociar com várias fábricas.

- Se a sua prioridade é desempenho, fiabilidade e um sistema chave-na-mão (e está disposto a pagar por isso), um Sistema baseado em CAN de um fornecedor respeitável pode poupar-lhe dores de cabeça e acrescentar valor ao seu produto (a um custo mais elevado, que esperamos que recupere através de um preço mais elevado para as suas bicicletas ou de eficiências de volume).

Limitações e tendências futuras

Mesmo quando exaltamos as virtudes da UART e da CAN, vale a pena notar que a limitações do estado atual das comunicações entre bicicletas eléctricas e para onde as coisas podem estar a ir:

- Falta de normalização a nível da indústria: Ao contrário do mundo automóvel, onde quase todos os carros utilizam o barramento CAN e diagnósticos normalizados (OBD-II), a indústria das bicicletas eléctricas ainda está fragmentada. Existem não existe um protocolo universal único que todas as bicicletas eléctricas utilizam. As implementações UART variam (cada fabricante pode ter diferentes formatos de dados sobre UART), e as implementações CAN são frequentemente proprietárias. Isto é uma limitação para os consumidores e montadores de bicicletas - não é "plug and play" entre diferentes marcas. Não se pode pegar num ecrã qualquer e esperar que funcione com um controlador qualquer, a não ser que utilizem explicitamente o mesmo protocolo e firmware. EnergyBus é um esforço promissor de normalização (com o CANopen CiA-454 a definir mensagens para componentes de bicicletas eléctricas), mas ainda não é generalizado. Se o EnergyBus ou normas semelhantes ganharem força, poderemos ver componentes verdadeiramente interoperáveis - por exemplo, uma bateria do fabricante X pode ser utilizada com um sistema de motor do fabricante Y, com o protocolo baseado no CANopen a garantir que se entendem. Isto beneficiaria os compradores B2B (mais opções de fornecedores) e os consumidores (mais opções de atualização/reparação). No entanto, os intervenientes do sector também têm motivações comerciais para manter sistemas proprietários (para fidelizar os clientes). A tensão entre normalização vs. controlo proprietário irá moldar o futuro dos protocolos das bicicletas eléctricas.

- Largura de banda e necessidades de dados: Atualmente, as comunicações das bicicletas eléctricas são relativamente pouco detalhadas. Mas as futuras bicicletas eléctricas poderão transmitir mais informações - imagine-se a recolha de dados de alta frequência do sensor de binário, ou métricas de potência de alta resolução para fins de formação, ou mesmo vídeo de câmaras para segurança. O CAN a velocidades clássicas pode tornar-se um ponto de estrangulamento se for necessário enviar muitos dados. A indústria automóvel tem o CAN-FD (uma versão alargada do CAN com quadros de dados maiores e maior débito) e outros protocolos como o Ethernet para necessidades de grande largura de banda. Para as bicicletas eléctricas, o CAN-FD poderia eventualmente aparecer, se necessário, ou o BLE/Wi-Fi para descarregar registos de dados. Comunicação sem fios pode também complementar os protocolos com fios: muitas bicicletas eléctricas já utilizam o Bluetooth Low Energy para ligar a bicicleta a uma aplicação para smartphone. Isto está fora do âmbito do sistema elétrico interno, mas vale a pena referir como um canal paralelo. Talvez, no futuro, algumas e-bikes mais simples possam mesmo prescindir de um ecrã com fios e utilizar um módulo sem fios para um telefone - embora o controlo crítico (como os sinais do acelerador ou do travão) permaneça provavelmente com fios para maior fiabilidade. Nas frotas de carga, poderemos assistir a uma maior integração da comunicação V2X (vehicle-to-everything) - e-bikes a comunicar com sistemas de logística ou infra-estruturas de tráfego, que, mais uma vez, seriam colocadas por cima do sistema central de bus CAN.

- Preocupações com a segurança: À medida que as bicicletas eléctricas se ligam e utilizam comunicações mais complexas, cibersegurança torna-se uma preocupação. Um sistema UART sem conetividade externa é praticamente imune à pirataria informática (alguém teria de aceder fisicamente aos fios). Mas um bus CAN que faça interface com um módulo Bluetooth ou um módulo GSM (para localização de frotas) apresenta potenciais vulnerabilidades. Os fabricantes terão de garantir que os seus protocolos (especialmente as interfaces sem fios para o barramento) são seguros para impedir o controlo malicioso (imagine-se um hack IoT que poderia desativar remotamente uma frota de bicicletas de entrega - um cenário rebuscado, mas teoricamente possível se não for protegido). Os protocolos proprietários são, por natureza, de alguma forma seguros através da obscuridade, mas à medida que o CAN se torna comum nas bicicletas eléctricas, os maus actores podem tentar injetar mensagens CAN através de uma porta exposta. Assim, poderemos ver mais encriptação ou autenticação nas comunicações das bicicletas eléctricas no futuro.

- Experiência do utilizador: Em última análise, qualquer que seja o protocolo utilizado, este deve proporcionar uma boa experiência ao utilizador. Os condutores preocupam-se com coisas como um fornecimento de energia suave, informações exactas no ecrã e funcionalidades de segurança que funcionem quando necessário. Uma limitação dos primeiros sistemas baseados no CAN era o facto de, por vezes, serem também bloqueados - os utilizadores sentiam-se frustrados por não poderem sequer alterar preferências simples. À medida que os sistemas amadurecem, os fabricantes podem encontrar formas de dar flexibilidade aos utilizadores (através de aplicações ou definições autorizadas) sem comprometer o controlo. Por exemplo, talvez uma aplicação possa permitir uma afinação limitada (dentro de limites seguros) mesmo num sistema CAN, ou permitir que acessórios de terceiros certificados comuniquem no bus (talvez utilizando mensagens padrão EnergyBus). Podemos esperar um pouco mais de abertura à medida que os protocolos se normalizam, ironicamente mesmo num mundo CAN.

Para concluir, o O sistema de comunicação eléctrica das bicicletas eléctricas - quer seja UART ou CAN - é crucial para o desempenho, a segurança e a modularidade da bicicleta. Os engenheiros que projectam bicicletas eléctricas têm de equilibrar a simplicidade da UART com a sofisticação da CAN. Os compradores B2B devem considerar como a escolha afecta o custo, a cadeia de fornecimento e a proposta de valor do seu produto. A indústria parece estar a tender para o barramento CAN à medida que as bicicletas eléctricas evoluem para máquinas mais conectadas e capazes, mas os sistemas baseados em UART continuarão provavelmente em paralelo com os modelos mais simples e de baixo custo durante algum tempo (afinal, são "suficientemente bons" para um enorme segmento de ciclistas).

Ao compreender estes protocolos de comunicação - essencialmente os linguagem eléctrica das bicicletas eléctricas - ganha-se uma apreciação muito mais profunda do modo como uma bicicleta eléctrica funciona internamente. Desde a torção do acelerador ou a pressão no pedal, até ao impulso do motor e aos números no ecrã, tudo isto é possibilitado por bits e bytes que passam por fios, garantindo que a bateria, o motor e o ciclista estão em sincronia. E quer se trate de uma elegante bicicleta eléctrica urbana ou de um pesado veículo de transporte de carga, essa harmonia é o que faz com que a viagem seja fácil e segura. No final, o objetivo de qualquer protocolo é fazer com que a tecnologia passe para segundo plano, para que os ciclistas possam simplesmente desfrutar da viagem - mas agora, esperamos, com um pouco de conhecimento da impressionante coordenação eletrónica que acontece debaixo dos seus pés.

Fontes:

- Guia da Ebike Qiolor - "Como escolher um ecrã compatível para o seu controlador de bicicleta eléctrica" (2025) - debate sobre as linguagens UART e CANBUS e a importância da correspondência entre os protocolos.

- Velco.tech - "CAN vs UART: diferenças entre os modos de comunicação" (2024) - explicar a simplicidade da UART em comparação com as capacidades de rede do CAN e enumerar as suas vantagens/limitações .

- Centro de Ajuda Biktrix - "O que são os protocolos CANBUS e UART?" - visão centrada no utilizador sobre o modo como o CAN bloqueia as definições (limite de velocidade fixo) e o UART permite modificações, além de uma comparação da permutabilidade dos ecrãs.

- IoT Venture (estudo de caso com a frota CYCLE) - descrição dos benefícios da integração do CAN em frotas de bicicletas eléctricas: acesso a dados de manutenção, desativação remota do motor, actualizações OTA .

- Conhecimento da HOVSCO - "Que caraterísticas de segurança têm as bicicletas eléctricas?" - notas sobre a norma EN 15194 (UE), que garante os limites de velocidade/potência e a durabilidade, e a norma UL 2849 (EUA), que se centra na segurança eléctrica/contra incêndios, bem como a menção da norma DIN 79010 para a segurança das bicicletas de carga .

- Texas Instruments App Note - "Considerações sobre o design de hardware para uma bicicleta eléctrica com motor BLDC" - forneceu diagramas de blocos de sistemas típicos de bicicletas eléctricas e uma perspetiva da eletrónica de controlo.

- Letrigo Ebike Conhecimento - "Explicação da cablagem do ecrã da bicicleta eléctrica" - pormenores sobre a cablagem e os conectores (Higo/Julet) e adverte para o facto de não existir uma norma universal para a cablagem, salientando a correspondência adequada das ligações e uma cablagem robusta para a integridade do sinal.

- Norma EnergyBus - Introdução da Kvaser - descrevendo o EnergyBus como uma norma aberta baseada em CANopen para componentes LEV, para garantir a compatibilidade e a segurança entre fabricantes.