Στον κόσμο των ηλεκτρονικών ποδηλάτων και των ποδηλάτων φορτίου, η επικοινωνία δεν αφορά μόνο το Bluetooth ή τις εφαρμογές - αφορά τον τρόπο με τον οποίο τα διάφορα εξαρτήματα "μιλούν" μεταξύ τους στο εσωτερικό του οχήματος. Ένα από τα πιο συνηθισμένα και κρίσιμα πρωτόκολλα επικοινωνίας είναι UART (καθολικός ασύγχρονος δέκτης/μεταδότης).

Στο Regen, πιστεύουμε ότι η κατανόηση του τρόπου λειτουργίας πρωτοκόλλων όπως το UART βοηθά όχι μόνο τους μηχανικούς μας, αλλά και τους διαχειριστές στόλου, τους αγοραστές B2B και τους συνεργάτες OEM να λαμβάνουν καλύτερες αποφάσεις - είτε πρόκειται για την ενσωμάτωση μιας νέας οθόνης, είτε για την αποσφαλμάτωση ενός ελεγκτή, είτε για την προσαρμογή του δικού σας συστήματος ποδηλάτου μεταφοράς φορτίου.

Σε αυτό το άρθρο, θα αναλύσουμε:

- Τι είναι το UART και πώς λειτουργεί

- Ο ρόλος του στα ηλεκτρικά συστήματα ηλεκτρονικών ποδηλάτων

- UART έναντι άλλων πρωτοκόλλων επικοινωνίας

- Παραδείγματα εφαρμογών σε ηλεκτρονικά ποδήλατα και ποδήλατα φορτίου

- Περιορισμοί, ζητήματα ασφάλειας και συμμόρφωση

Ας αποκωδικοποιήσουμε αυτό το απαραίτητο -αλλά συχνά παραγνωρισμένο- πρωτόκολλο επικοινωνίας.

Για να μάθετε τι είναι τα πρωτόκολλα επικοινωνίας , ελέγξτε το : E-Πρωτόκολλα επικοινωνίας ποδηλάτων: Μηχανικοί και Αγοραστές

Τι είναι UART (καθολικός ασύγχρονος δέκτης/μεταδότης)?

UART σημαίνει Καθολικός ασύγχρονος δέκτης/πομπός - ένα πρωτόκολλο που βασίζεται σε υλικό για σειριακή επικοινωνία. Είναι ένας από τους παλαιότερους και απλούστερους τρόπους αποστολής και λήψης δεδομένων μεταξύ συσκευών.

Βασικά χαρακτηριστικά:

| Ακίνητα | Αξία |

|---|---|

| Τύπος | Ασύγχρονη σειριακή επικοινωνία |

| Καλωδίωση | Συνήθως 2 καλώδια (TX και RX), μερικές φορές με GND |

| Κατεύθυνση | Full-duplex (τα δεδομένα ρέουν και προς τις δύο κατευθύνσεις) |

| Μορφή δεδομένων | Βάση byte (8 bits, συν προαιρετικά start/stop/parity bits) |

| Ταχύτητα (ρυθμός Baud) | 9600 - 115200 bps κοινά για τα ηλεκτρονικά ποδήλατα |

Σε αντίθεση με πιο σύνθετα πρωτόκολλα όπως το CAN ή το I²C, το UART δεν χρειάζεται σήμα ρολογιού. Αντ' αυτού, οι δύο συσκευές συμφωνούν για το ρυθμός baud (ταχύτητα bit) εκ των προτέρων.

Πώς λειτουργεί η UART μέσα σε ένα E-Bike

Σε ένα τυπικό ηλεκτρονικό ποδήλατο ή ηλεκτρονικό ποδήλατο φορτίου, το UART χρησιμοποιείται για επικοινωνία σημείο προς σημείο μεταξύ βασικών ηλεκτρονικών εξαρτημάτων:

- Ελεγκτής κινητήρα ↔️ Οθόνη

- Σύστημα διαχείρισης μπαταριών (BMS) ↔️ Ελεγκτής

- Οθόνη ↔️ Αισθητήρας γκαζιού ή PAS

- Μονάδα Bluetooth ↔️ Ελεγκτής

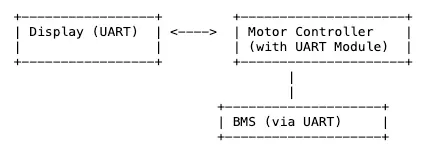

Ακολουθεί ένα απλουστευμένο διάγραμμα της χρήσης του UART σε ένα ηλεκτρονικό ποδήλατο φορτίου εμπρόσθιας φόρτωσης:

Κάθε σύνδεση UART είναι συνήθως αφιερωμένο - δεν υπάρχει διαμοιρασμός όπως στα λεωφορεία CAN. Αυτή η απλότητα είναι ιδανική για ενσωματωμένα συστήματα με λιγότερους κόμβους και χαμηλές απαιτήσεις ισχύος.

Γιατί UART; Βασικά πλεονεκτήματα για συστήματα E-Bike

Ενώ τα σύγχρονα πρωτόκολλα επικοινωνίας όπως το CAN (Controller Area Network) κερδίζουν έδαφος, το UART παραμένει κυρίαρχο στα σχέδια ηλεκτρονικών ποδηλάτων χαμηλής και μεσαίας κατηγορίας - και για καλό λόγο:

✅ Απλότητα και χαμηλό κόστος

Το UART δεν χρειάζεται πρόσθετες γραμμές ρολογιού, ούτε πολύπλοκα ολοκληρωμένα κυκλώματα ελεγκτή και ελάχιστη επιβάρυνση λογισμικού. Αυτό είναι τέλειο για μοντέλα με ευαίσθητο κόστος ή μινιμαλιστικά ποδήλατα φορτίου.

✅ Συμβατότητα

Πολλά παλαιά και φιλικά προς τον προϋπολογισμό εξαρτήματα - ειδικά σε κινητήρες και οθόνες που προέρχονται από την Ασία και τον Ειρηνικό - χρησιμοποιούν από προεπιλογή UART. Είναι ένα de facto πρότυπο σε κομβικά και μεσαία κινητήρια μέσα από εταιρείες όπως η Bafang (παραλλαγές UART), η Ananda και η Tongsheng.

✅ Εύκολη αποσφαλμάτωση

Μπορείτε εύκολα να "κρυφακούσετε" τις γραμμές UART με έναν μετατροπέα USB σε TTL και εργαλεία ανοικτού κώδικα όπως το Σειριακή παρακολούθηση ή PuTTY - κάτι που δεν γίνεται εύκολα με τους διαύλους CAN ή LIN.

UART vs CAN vs I²C: Μια γρήγορη σύγκριση

| Χαρακτηριστικό | UART | CAN | I²C |

|---|---|---|---|

| Τοπολογία | Σημείο-προς-σημείο | Πολλαπλών κόμβων (δίαυλος) | Multi-master (μικρής εμβέλειας) |

| Ταχύτητα | Έως 1 Mbps (συνήθως χαμηλότερα) | Έως 1 Mbps | Έως 3,4 Mbps |

| Πολυπλοκότητα | Χαμηλός | Μεσαία-υψηλή | Μέσον |

| Αξιοπιστία (θόρυβος) | Μέσον | Ψηλά | Χαμηλό-Μέτριο |

| Πλαισίωση μηνυμάτων | Χειροκίνητο (καθορισμένο από λογισμικό) | Ενσωματωμένο με ID & CRC | Απλή διευθυνσιοδότηση |

| Χρήση σε ηλεκτρονικά ποδήλατα | Συστήματα Legacy & χαμηλού κόστους | Premium και εμπορικοί στόλοι | Αισθητήρες & μονάδες μπαταρίας |

Στην πράξη:

- Το UART είναι πιο συνηθισμένο σε ηλεκτρονικά ποδήλατα και ποδήλατα φορτίου καταναλωτικού επιπέδου.

- Το CAN χρησιμοποιείται σε συστήματα υψηλών προδιαγραφών ή συστήματα στόλου (π.χ. Bosch, Shimano STEPS εμπορικά συστήματα).

- Το I²C περιορίζεται συνήθως στην επικοινωνία εντός της πλακέτας.

Περιπτώσεις χρήσης UART σε ποδήλατα φορτίου E-Bikes: Παραδείγματα πραγματικού κόσμου

1. Εμφάνιση του ελεγκτή ↔️

Οι περισσότερες βασικές οθόνες ηλεκτρονικών ποδηλάτων - όπως οι Bafang 500C, C965 ή SW102 - χρησιμοποιούν UART για την επικοινωνία ταχύτητας, λειτουργίας, τάσης μπαταρίας και κωδικών σφάλματος. Η Regen έχει συνεργαστεί με πολλούς πελάτες για να Προσαρμογή του UI της οθόνης μέσω ακολουθιών εντολών UART.

2. Μονάδα Bluetooth ή IoT ↔️ Ελεγκτής

Εάν θέλετε να τοποθετήσετε εκ των υστέρων απομακρυσμένη διάγνωση ή ένα GPS tracker, πολλές μονάδες Bluetooth UART (π.χ. HC-05, HM-10) μπορούν να διασυνδεθούν με τον ελεγκτή μέσω TX/RX, επιτρέποντας βασικές εντολές και αναφορές δεδομένων.

3. Δοκιμές & ενημερώσεις υλικολογισμικού

Το UART χρησιμοποιείται συνήθως για αναβοσβήσιμο υλικολογισμικού των ελεγκτών και των οθονών. Κατά τη διάρκεια των δοκιμών πριν από την αποστολή, οι μηχανικοί QA της Regen συχνά συνδέονται στη θύρα UART του ελεγκτή για να καταγράφουν τις αποκρίσεις του κινητήρα και των αισθητήρων.

Περιορισμοί και προβληματισμοί

Παρά τα πλεονεκτήματά του, το UART έχει αρκετούς τεχνικούς περιορισμούς που πρέπει να ληφθούν υπόψη, ιδίως σε μεγάλα ή εμπορικής χρήσης ηλεκτρονικά ποδήλατα φορτίου:

❌ Δεν υπάρχει δυνατότητα διαύλου

Δεν μπορείτε να συνδέσετε πολλές συσκευές στην ίδια γραμμή. Αυτό περιορίζει την επεκτασιμότητα σε πιο σύνθετα συστήματα με GPS, έξυπνες κλειδαριές, συστήματα φωτισμού κ.λπ.

❌ Χωρίς διόρθωση σφαλμάτων

Το βασικό UART δεν περιλαμβάνει CRC ή άθροισμα ελέγχου. Εάν υπάρχει θόρυβος ή απώλεια πακέτων, τα μηνύματα ενδέχεται να παραμορφωθούν. Ορισμένοι προμηθευτές προσθέτουν ιδιόκτητες μεθόδους ελέγχου αθροίσματος, αλλά δεν είναι εγγενείς.

❌ Ο ρυθμός Baud πρέπει να ταιριάζει

Η αναντιστοιχία στις ρυθμίσεις ρυθμού baud μπορεί να οδηγήσει σε ολική αποτυχία επικοινωνίας - ειδικά κατά τη διάρκεια αναβαθμίσεων μετά την αγορά ή αντικαταστάσεων εξαρτημάτων.

Συμβουλή από το Regen: Πάντα να επιβεβαιώνετε τις προδιαγραφές UART όταν ανταλλάσσετε οθόνες ή ελεγκτές τρίτων κατασκευαστών - ειδικά σε ποδήλατα φορτίου με μακρύτερα καλώδια, τα οποία είναι πιο ευαίσθητα σε παρεμβολές.

Ασφάλεια, συμμόρφωση και βιομηχανικά πρότυπα

Ενώ το UART είναι ένα τεχνικό πρωτόκολλο, η σωστή εφαρμογή του μπορεί να επηρεάσει ασφάλεια και συμμόρφωση. Για παράδειγμα:

- EN 15194:2017 (πρότυπο της ΕΕ για τα EPAC) απαιτεί αξιόπιστη επικοινωνία και ανίχνευση σφαλμάτων με υποβοήθηση ισχύος.

- Συμμόρφωση CE ελέγχει για ηλεκτρομαγνητικές παρεμβολές (EMI), οι οποίες μπορεί να επηρεάσουν τη σταθερότητα του UART.

- EN 50604-1:2016 (πρότυπο BMS μπαταρίας) συνιστά οι ψηφιακές γραμμές επικοινωνίας να είναι θωρακισμένες, γειωμένες και κατάλληλα τερματισμένες.

Το Regen ακολουθεί αυτές τις συστάσεις σε όλα τα Διαμορφώσεις OEM. Σε ποδήλατα φορτίου υψηλής ισχύος που χρησιμοποιούνται για logistics, συνιστούμε συχνά την αναβάθμιση των καλωδίων UART σε θωρακισμένες παραλλαγές και τη χρήση συνδετήρες με μηχανισμούς ασφάλισης (π.χ. αδιάβροχα βύσματα Higo) για την αποφυγή τυχαίων αποσυνδέσεων.

Πότε να επιλέξετε UART - και πότε όχι

| Περίπτωση χρήσης | Καταλληλότητα UART |

|---|---|

| Βασικό ποδήλατο φορτίου με πεντάλ | ✅ Άριστη εφαρμογή |

| Εξαρτήματα μεταγενέστερης αγοράς για ηλεκτρονικά ποδήλατα | ✅ Plug-and-play φιλικό |

| Στόλος με πολλαπλές έξυπνες μονάδες | ❌ Καλύτερα να χρησιμοποιήσετε το CAN |

| Μεγάλη διαδρομή καλωδίων (>1,5 m) | ⚠ Χρειάζεται θωράκιση |

| Απομακρυσμένα διαγνωστικά ή ενημερώσεις OTA | ⚠ Περιορισμένες δυνατότητες |

| Έλεγχος σε πραγματικό χρόνο για κρίσιμα θέματα ασφάλειας | ❌ Χρήση CAN ή SPI |

Στην Regen, βοηθάμε τους πελάτες να αποφασίσουν μεταξύ UART, CAN και υβριδικών συστημάτων με βάση τα σενάριο χρήσης, βαθμίδα προϊόντος, και μακροπρόθεσμη στρατηγική συντήρησης.

Τι ακολουθεί; Η άνοδος της υβριδικής επικοινωνίας στα ηλεκτρονικά ποδήλατα

Ενώ το UART παραμένει δημοφιλές, παρατηρούμε μια αλλαγή:

- Ελεγκτές διπλού πρωτοκόλλου: Ορισμένοι ελεγκτές της Bafang υποστηρίζουν τόσο UART όσο και CAN, δίνοντας ευελιξία στους κατασκευαστές ΟΕΜ κατά τη διάρκεια αναβαθμίσεων.

- Έξυπνες οθόνες: Μονάδες όπως το DP-C245 υποστηρίζουν τώρα γέφυρες UART-to-BLE, επιτρέποντας την ενσωμάτωση εφαρμογών, διατηρώντας παράλληλα την παραδοσιακή καλωδίωση.

- Εξομοίωση CAN-over-UART: Πειραματικές ρυθμίσεις επιτρέπουν βασική πολυπλεξία μέσω UART - ιδανικό για IoT εισαγωγικού επιπέδου σε στόλους φορτίων.

Στο Regen, συνεργαζόμαστε ήδη με πελάτες σε CAN-ενσωματωμένα ποδήλατα φορτίου με UART fallback - συνδυάζοντας την απλότητα με την επεκτασιμότητα.

Μόνο 20 ποδήλατα MOQ για να ξεκινήσετε

Προσαρμόσιμο ποδήλατο E-Cargo - RS01

Είτε είστε μια αναπτυσσόμενη μάρκα είτε ένα κατάστημα της γειτονιάς, τα βαρέως τύπου ποδήλατα φορτίου μας είναι το εισιτήριό σας για τον αναπτυσσόμενο κόσμο των φιλικών προς το περιβάλλον παραδόσεων. Ας ξεκινήσουμε!

Τελικές σκέψεις: UART εξακολουθεί να τροφοδοτεί το καθημερινό ηλεκτρονικό ποδήλατο

Παρά την ηλικία του, Το UART απέχει πολύ από το να είναι παρωχημένο. Συνεχίζει να τροφοδοτεί εκατομμύρια ηλεκτρονικά ποδήλατα και ποδήλατα φορτίου - από οικογενειακά ποδήλατα αρχικής κατηγορίας μέχρι ποδήλατα κοινής ωφέλειας σε πόλεις όπως το Βερολίνο και το Άμστερνταμ.

Η κατανόηση της UART βοηθά τους μηχανικούς, τους αγοραστές ΟΕΜ και τους διαχειριστές στόλου να:

- Σχεδιάστε καλύτερα συστήματα

- Αποφύγετε δαπανηρά σφάλματα συμβατότητας

- Προσαρμογή χαρακτηριστικών για τους τελικούς χρήστες τους

Είτε κατασκευάζετε το πρώτο σας ποδήλατο φορτίου είτε διαχειρίζεστε έναν στόλο 500 ποδηλάτων, το Regen είναι εδώ για να σας βοηθήσει να επιλέξετε τη σωστή επικοινωνιακή βάση.

Κατάλογος αναφοράς

- Bafang Electric. (2024). Εγχειρίδια συστήματος Bafang. https://www.bafang-e.com

- ΕΝ 15194:2017. Ποδήλατα - Ποδήλατα με ηλεκτρική υποβοήθηση - EPAC Bicycles. CEN.

- EN 50604-1:2016. Δευτερεύουσες μπαταρίες λιθίου για ελαφριά EVs. IEC.

- STMicroelectronics. (2022). Βασικά στοιχεία επικοινωνίας UART. https://www.st.com

- TI. (2021). Ασύγχρονη σειριακή επικοινωνία (UART). Texas Instruments.

- Συστήματα eBike της Bosch. (2024). Τεχνική επισκόπηση: eBikes. Bosch Mobility.