In the world of e-bikes and cargo bikes, communication isn’t just about Bluetooth or apps — it’s about how different components “talk” to each other inside the vehicle. One of the most common and crucial communication protocols is UART (Universal Asynchronous Receiver/Transmitter).

At Regen, we believe understanding how protocols like UART work helps not just our engineers, but also fleet managers, B2B buyers, and OEM partners make better decisions — whether you’re integrating a new display, debugging a controller, or customising your own cargo bike system.

In this article, we’ll break down:

- What UART is and how it works

- Its role in e-bike electrical systems

- UART vs other communication protocols

- Application examples in e-bikes and cargo bikes

- Limitations, safety considerations, and compliance

Let’s decode this essential—but often overlooked—communication protocol.

To learn what is the Communication Protocols , check our : E-Bike Communication Protocols: A Complete Guide for Engineers and Buyers

What is UART (Universal Asynchronous Receiver/Transmitter)?

UART stands for Universal Asynchronous Receiver/Transmitter — a hardware-based protocol for serial communication. It’s one of the oldest and simplest ways to send and receive data between devices.

Key characteristics:

| Property | Value |

|---|---|

| Type | Asynchronous Serial Communication |

| Wiring | Usually 2 wires (TX and RX), sometimes with GND |

| Direction | Full-duplex (data flows both ways) |

| Data Format | Byte-based (8 bits, plus optional start/stop/parity bits) |

| Speed (Baud Rate) | 9600 – 115200 bps common for e-bikes |

Unlike more complex protocols like CAN or I²C, UART doesn’t need a clock signal. Instead, both devices agree on the baud rate (bit speed) beforehand.

How UART Works Inside an E-Bike

In a typical e-bike or cargo e-bike, UART is used for point-to-point communication between key electronic components:

- Motor Controller ↔️ Display

- Battery Management System (BMS) ↔️ Controller

- Display ↔️ Throttle or PAS sensor

- Bluetooth Module ↔️ Controller

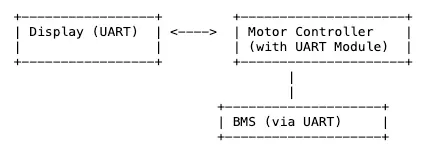

Here’s a simplified diagram of UART use in a front-loading cargo e-bike:

Each UART connection is usually dedicated — no sharing like in CAN buses. This simplicity is ideal for embedded systems with fewer nodes and low power demands.

Why UART? Key Advantages for E-Bike Systems

While modern communication protocols like CAN (Controller Area Network) are gaining ground, UART remains dominant in low-to-mid-range e-bike designs — and for good reason:

✅ Simplicity and Low Cost

UART needs no additional clock lines, no complex controller ICs, and minimal software overhead. That’s perfect for cost-sensitive models or minimalist cargo bikes.

✅ Compatibility

Many legacy and budget-friendly components — especially in Asia-Pacific–sourced motors and displays — default to UART. It’s a de facto standard in hubs and mid-drives from companies like Bafang (UART variants), Ananda, and Tongsheng.

✅ Easy Debugging

You can easily “listen in” on UART lines with a USB-to-TTL converter and open-source tools like Serial Monitor or PuTTY — something not easily done with CAN or LIN buses.

UART vs CAN vs I²C: A Quick Comparison

| Feature | UART | CAN | I²C |

|---|---|---|---|

| Topology | Point-to-point | Multi-node (bus) | Multi-master (short range) |

| Speed | Up to 1 Mbps (usually lower) | Up to 1 Mbps | Up to 3.4 Mbps |

| Complexity | Low | Medium–High | Medium |

| Reliability (noise) | Medium | High | Low–Medium |

| Message Framing | Manual (software-defined) | Built-in with ID & CRC | Simple Addressing |

| Use in E-Bikes | Legacy & Low-Cost Systems | Premium and commercial fleets | Sensors & battery modules |

In practice:

- UART is most common in consumer-level e-bikes and cargo bikes.

- CAN is used in high-end or fleet-grade systems (e.g., Bosch, Shimano STEPS commercial systems).

- I²C is usually confined to intra-PCB communication.

UART Use Cases in Cargo E-Bikes: Real-World Examples

1. Display ↔️ Controller

Most basic e-bike displays — such as Bafang 500C, C965, or SW102 — use UART to communicate speed, mode, battery voltage, and error codes. Regen has worked with multiple clients to customise display UI through UART command sequences.

2. Bluetooth or IoT Module ↔️ Controller

If you want to retrofit remote diagnostics or a GPS tracker, many Bluetooth UART modules (e.g. HC-05, HM-10) can interface with the controller via TX/RX, allowing basic commands and data reporting.

3. Testing & Firmware Updates

UART is commonly used for firmware flashing of controllers and displays. During pre-shipment testing, Regen’s QA engineers often connect to the controller’s UART port to log motor and sensor responses.

Limitations and Considerations

Despite its strengths, UART has several technical limitations to consider, especially in large or commercial-grade cargo e-bikes:

❌ No Bus Capability

You can’t connect multiple devices on the same line. That limits scalability in more complex systems with GPS, smart locks, lighting systems, etc.

❌ No Error Correction

Basic UART doesn’t include CRC or checksum. If there’s noise or packet loss, messages might get garbled. Some vendors add proprietary checksum methods, but it’s not native.

❌ Baud Rate Must Match

Mismatch in baud rate settings can lead to total communication failure — especially during aftermarket upgrades or part replacements.

Tip from Regen: Always confirm UART specs when swapping third-party displays or controllers — especially on cargo bikes with longer cable runs, which are more susceptible to interference.

Safety, Compliance, and Industry Standards

While UART is a technical protocol, its correct implementation can impact safety and compliance. For example:

- EN 15194:2017 (EU standard for EPACs) requires reliable power-assist communication and error detection.

- CE compliance checks for EMI (electromagnetic interference) which can affect UART stability.

- EN 50604-1:2016 (battery BMS standard) recommends digital communication lines be shielded, grounded, and properly terminated.

Regen follows these recommendations in all OEM configurations. In high-power cargo bikes used for logistics, we often recommend upgrading UART cables to shielded variants and using connectors with locking mechanisms (e.g., Higo waterproof plugs) to prevent accidental disconnections.

When to Choose UART — And When Not To

| Use Case | UART Suitability |

|---|---|

| Basic pedal-assist cargo bike | ✅ Excellent fit |

| Aftermarket e-bike kits | ✅ Plug-and-play friendly |

| Fleet with multiple smart modules | ❌ Better to use CAN |

| Long cable runs (>1.5 m) | ⚠ Needs shielding |

| Remote diagnostics or OTA updates | ⚠ Limited capabilities |

| Real-time safety-critical control | ❌ Use CAN or SPI |

At Regen, we help clients decide between UART, CAN, and hybrid systems based on their use scenario, product tier, and long-term maintenance strategy.

What’s Next? The Rise of Hybrid Communication in E-Bikes

While UART remains popular, we are seeing a shift:

- Dual-Protocol Controllers: Some Bafang controllers support both UART and CAN, giving OEMs flexibility during upgrades.

- Smart Displays: Units like the DP-C245 now support UART-to-BLE bridges, enabling app integration while retaining legacy wiring.

- CAN-over-UART Emulation: Experimental setups allow basic multiplexing over UART — ideal for entry-level IoT in cargo fleets.

At Regen, we are already working with clients on CAN-integrated cargo bikes with UART fallback — combining simplicity with scalability.

Only 20 MOQ Bikes to Get Started

Customizable E-Cargo Bike - RS01

Whether you’re a growing brand or a neighborhood store, our heavy-duty cargo bikes are your ticket into the booming world of eco-friendly delivery. Let’s roll!

Final Thoughts: UART Still Powers the Everyday E-Bike

Despite its age, UART is far from obsolete. It continues to power millions of e-bikes and cargo bikes — from entry-level family commuters to utility bikes in cities like Berlin and Amsterdam.

Understanding UART helps engineers, OEM buyers, and fleet managers alike to:

- Design better systems

- Avoid costly compatibility errors

- Customise features for their end users

Whether you’re building your first cargo bike or managing a 500-bike fleet, Regen is here to help you choose the right communication backbone.

Reference List

- Bafang Electric. (2024). Bafang System Manuals. https://www.bafang-e.com

- EN 15194:2017. Cycles – Electrically power assisted cycles – EPAC Bicycles. CEN.

- EN 50604-1:2016. Secondary lithium batteries for light EVs. IEC.

- STMicroelectronics. (2022). UART Communication Basics. https://www.st.com

- TI. (2021). Asynchronous Serial Communication (UART). Texas Instruments.

- Bosch eBike Systems. (2024). Technical Overview: Communication Protocols in eBikes. Bosch Mobility.